QATAR

Pipe Details

- 152.4-mm (6-inch) gas line experienced corrosion

- 7-m (23-ft) section of damaged pipe

Summary

- 4-mm (6-inch) gas line experienced corrosion over a 7-m (23-ft) section

- ThermoWrap™ MT restored integrity to the damaged line

- 6 trained and qualified technicians repaired the damage

- No hot work

- No disruption to operations

- No environmental impact

Inspections at a fertilizer plant in Qatar revealed a gas line in need of immediate repair. Internal corrosion had damaged a 7-m (23-ft) section of a 152.4-mm (6-inch) line in a location that posed access challenges.

Experience with several solution providers in the region had revealed poor chemical compatibility on previous projects, and the owner had sourced better repairs from CSNRI. Over the course of four years, CSNRI successfully addressed a range of integrity issues and had established a track record for providing a swift response and superior solutions.

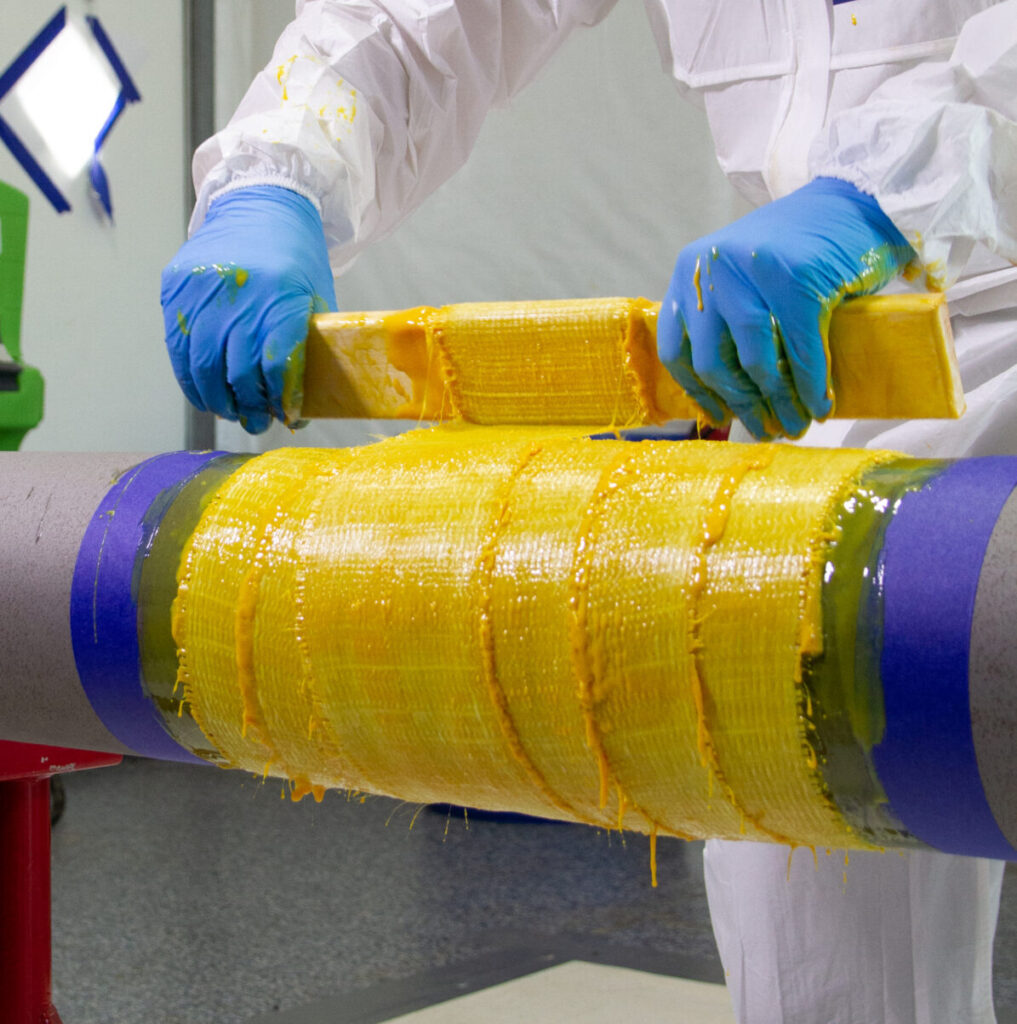

Based on engineering and qualification testing, CSNRI determined that the ThermoWrap MT system was the most appropriate solution for the corroded line. ThermoWrap MT is a custom engineered repair system that uses a fiberglass, composite-reinforced coating to deliver high strength characteristics. It is used routinely in chemical processing lines to repair corroded or damaged piping with harsh chemical services.

With the repair designed, a team of trained and qualified installers from a local contractor arrived on site and began preparing the pipe surface for the composite system installation. Once the pipe surface was ready, the technicians applied ThermoWrap MT to the full length of the damaged line, rapidly completing the repair.

Using no special equipment, the team delivered a fast and reliable composite repair without introducing hot work, taking the line out of service, or disrupting operations. Once again, CSNRI designed a reliable composite solution that addressed the owner’s asset integrity challenge without negatively impacting productivity.