WATER/WASTEWATER

Background

The Lucas County Interceptor Sewer No. 500 was originally constructed in the 1970s and was showing signs of deterioration involving spalling concrete and exposed steel reinforcement. The downstream section of this 90” reinforced concrete interceptor was successfully rehabilitated in October, 2018 with the GeoSpray spray on lining as a preventative maintenance measure before the issue became too severe.

The recent Phase II project involved lining a 1943’upstream section of the 90” interceptor Sewer No. 500. As with the earlier Phase I project, the GeoSpray material was used again by the low bidder applicator.

The city consultant responsible for the rehabilitation of both project phases had worked with GeoTree Solutions’ Regional Sales Manager, Dave Keaffaber in the past and was aware of the GeoSpray geopolymer mortar system’s benefits and advantages.

The project challenges warranted a solution that once again included the geopolymer lining option. The low bidder for the phase II project was GeoTree’s installation partner, Michels who completed the required lining work. The sewer is classified as a highly corrosive environment. These applications require rehabilitation using a product which is impervious and resistant to the damage that can be caused by the corrosive and abrasive influences frequently found in these environments.

Solution

With a large area to rehabilitate, the project was split into two phases. In October 2018, Michels installed GeoTree’s GeoSpray AMS, a product which saw the tried and tested GeoSpray geopolymer system applied to 1,800' of the 90” concrete sewer. The GeoSpray lining was then covered with a final sealant coating (AMS) which made the surface impervious to corrosive fluids.

By the time the second phase of the project was due to start, GeoTree had launched the GeoSpray HCE material, a new product that supersedes the old AMS system. GeoSpray HCE combines the structural GeoSpray and corrision resistant benefits into one easy-to-install product.

Michels was keen to use the HCE system as the elimination of the second postcoat step cut an estimated 25% off the time required for the product to be applied.

The eight-man team accessed the sewer via manholes and used the spin cast method to clean the heavy sediment build-up and carry out the lining install. The applicator skid used to spray the mortar was erected inside the sewer. They also had to be aware and mindful of rainfall which resulted in heavy infiltration of water leaking into the sewer. This shut down the install on several occasions.

Once the application was complete the team said they felt the new GepSpray HCE adhered better to the concrete sewer and left a better finish from an aesthetic perspective.

GeoTree’s Dave Keaffaber said: “We are excited to bring the HCE product to our customers as we know it makes installation a more streamlined process. We are pleased that this installation has proven the effectiveness of GeoSpray HCE.”

PROJECT DETAILS

Application: Interceptor Sewer Rehabilitation

Client: Lucas County (Ohio) Sanitary Engineer

Location: Holland, Ohio

Installation: September 2021

Installer:Michels

GeoSpray HCE Installation - Before and After

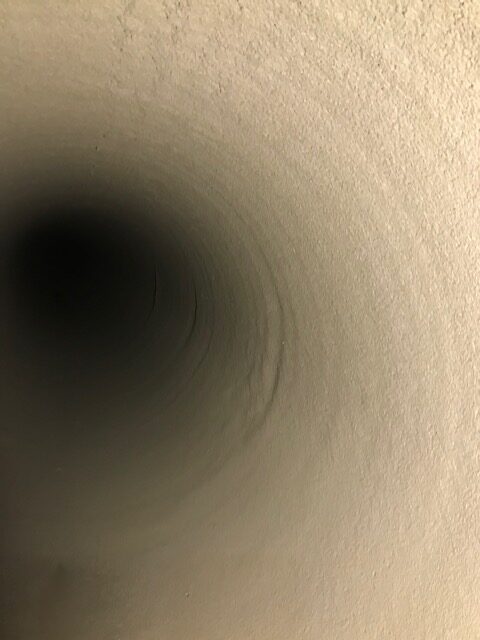

Before: Sewer showing signs of deterioration of existing concrete and heavy scale and sediment build up.