WATER/WASTEWATER

Overview

Montana Rail Link (MRL) is a Class II regional railroad company that operates more than 900 route miles of track in Montana and Idaho. Goods shipped by Montana Rail Link include coal, industrial products, grain, intermodal and vehicles. The State of Montana has major swings in climate conditions and soils and environmental influences that can be aggressive to steel and concrete structures, which is a concern for MRL. The company’s inspection group continuously reviews their infrastructure and identifies required structures and rail repairs.

Issue

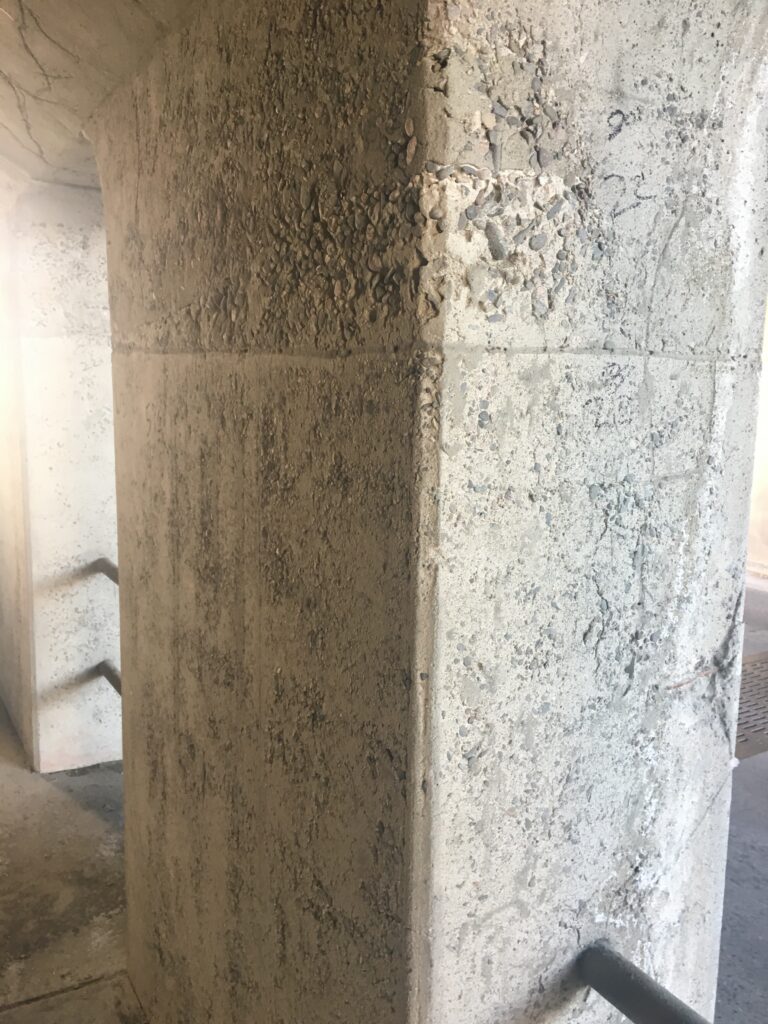

The inspection group identified a bridge in Laurel Montana that needed repairs as the concrete showed signs of distress due to climate and environment conditions. The below images highlight the condition of the concrete structures before the repair:

Existing Column, girder and wall condition

Solution

PROJECT DETAILS

Application: Railroad Bridge

Client: Montana Rail Link (MRL)

Location: Laurel, Montana

Installation: July 2020

Installer: Shotcrete Montana

MRL called Shotcrete Montana, based in Billings, Montana to resurface the foundation walls with a reinforced cementitious matrix system. This technology is engineered to prevent the distressed concrete from continuing to deteriorate. In reviewing options for conducting the repair, Shotcrete Montana decided to use a CFRP matrix in conjunction with a geopolymer repair mortar from GeoTree Solutions. Shotcrete Montana purchased the GeoTree geopolymer material and CFRP grid through a regional distribution company, Full Moon Enterprises.

The GeoTree geopolymer was chosen as it has the chemistry of a polymer that acts like an engineered stone and exhibits a range of high-performing physical properties including bond strength, tensile strength, flexural strength, and low permeability that exceeds cement mortars systems available. In addition, the flexibility in application allows the installer to work with complex geometry as the GeoTree geopolymer mortar can be poured, troweled, or sprayed.

The repair consisted of preparing the surface with a thorough cleaning, applying a thin layer of GeoTree geopolymer, applying the CFRP grid, spraying the GeoTree Geopolymer over the grid, and then hand trowelling to make a smooth surface for aesthetics according to the client guidelines.