STRUCTURAL STRENGTHENING

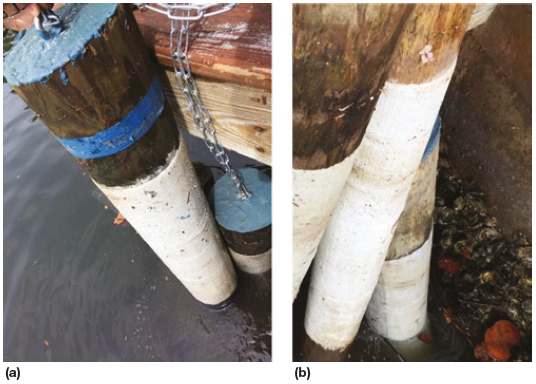

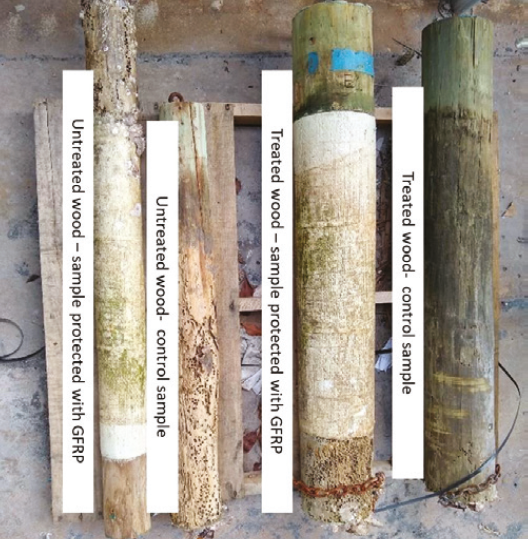

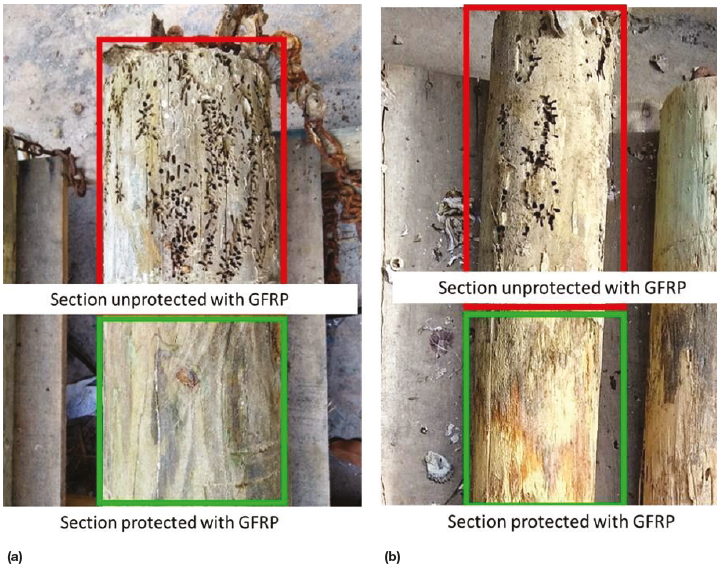

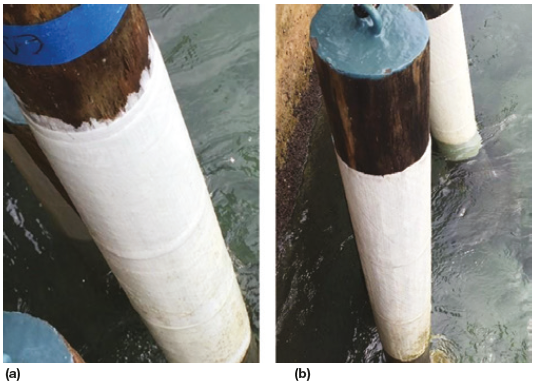

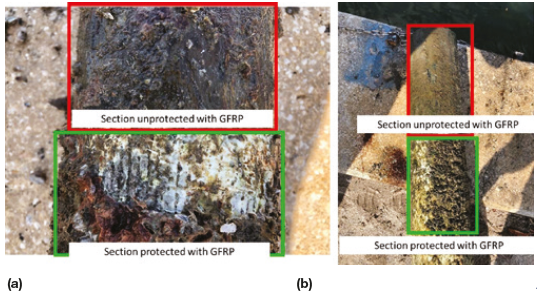

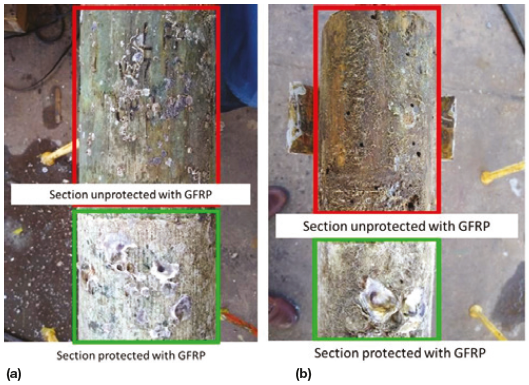

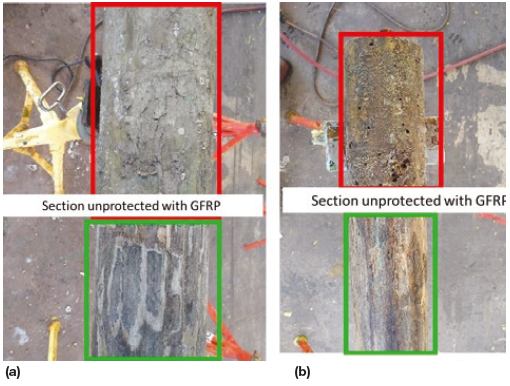

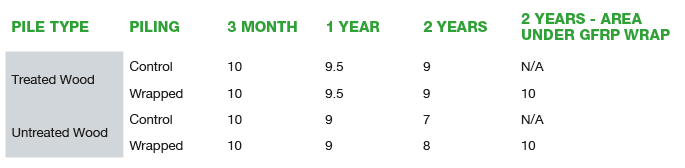

In order to ensure there is activity of marine borer attack, two types of pilings were wrapped and submerged at each location. The first type included 6in OD un-treated timber, commonly used to build residential fencing. The second type is 12in OD treated marine pilings. Inspection of the piles was completed at the 3-month, 1-year, and 2-year mark and testing was concluded after 2 years of submersion. A summary of the results based on the grading criteria of AWPA E5-15 are shown in Tables 2 and 3. It should be noted that the grading of the pilings wrapped with GFRP is based on the exposed wood sections of the pile, not under or on the GFRP wrap.

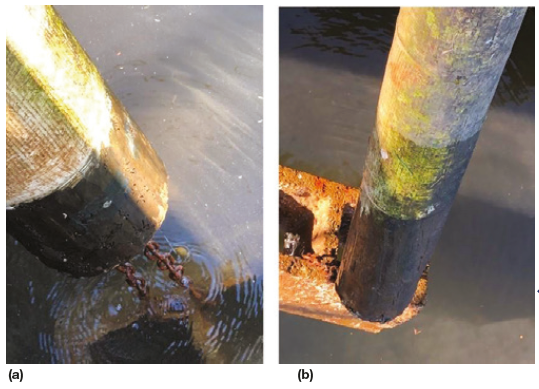

The results are very promising, showing great ability of the GFRP to protect and prevent attacks from marine borers. Figures 1, 2, 3, and 4 show the condition of the pilings from the canal water at 3month, 1 year, 2 year submersion mark and after the wraps were removed at the end of the test. Figure 5, 6, 7, and 8 show the condition of the pilings from the intracoastal waterway location.

The ability of the GFRP to prevent attacks and preserve the pilings is attributed to the creation of a barrier between the timber substrate and the GFRP, preventing the borers from penetrating and thriving on the timber substrate. Marine borers thrive in slow moving and shallow waters because of the high oxygen levels present in them. This is why it is believed the canal water pilings experienced more damage than the intracoastal pilings.

While this study was targeted for new pilings that need protection, the same technology has been used previously to wrap damaged piles. For hourglass shaped pilings, which have experienced extensive damage, a filler material is required to restore the original shape of the piling, prior to the application of the product.

The product used is a pre-saturated UV resistant glass FRP system that comes in hermetically sealed pouch, which cures in the presence of moisture and can be applied fully underwater. Check-out our website at www.cs-nri.com for more information and other similar products that are easy to install and can be used to protect your structure for decades to come.