Pipe Lining

ISSUE

Engineers from the Delaware Department of Transportation (DelDOT) identified the need to rehabilitate large diameter metal plate arch culverts that ranged from ~7’ x 10’ to ~10’ x 17’ totalling 608 LF. The existing pipes had significant deterioration including missing metal from the invert causing them to upheave. In addition, perforations in the crown and voids between the joints permitted infiltration, and fill material loss was evident in the travel lane above.

At DelDOT, any culvert more than 48” in diameter is considered a bridge. DelDOT project manager Jon Karam estimated that to carry out three full bridge replacements would take a minimum of six to nine months. This was an issue as there was an environmental deadline to be out of the stream, that ran through the culverts, by early March.

PROJECT DETAILS

Application: Large Diameter Metal Plate Arch Culverts

Client: Delaware DOT (DelDOT)

Location: New Castle County, Delaware

Project Engineer: Pennoni

Contractor: JJID

Sub-Contractor: Entech Construction

Date of installation: February 2022

SOLUTION

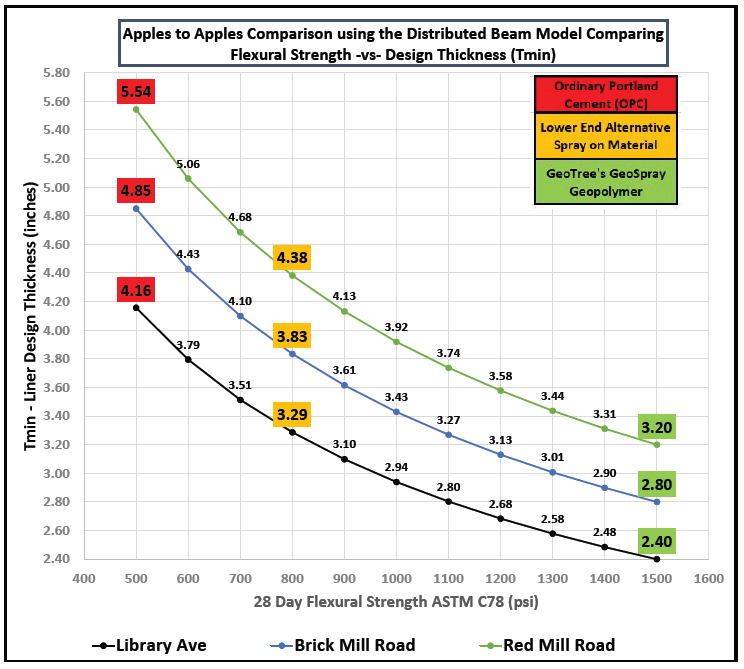

Aside from full replacement, DelDOT considered several rehabilitation options. Slip lining was eliminated as it decreased the culverts' hydraulic capacity. Cured in Place Pipe was not economically practical at the bridge’s size and Ordinary Portland Cement (OPC) lining was not considered due to challenges that occurred on other projects. It also delivered weaker flexural thickness than GeoSpray geopolymer. See figure 1 which shows the direct relationship between flexural strength and liner thickness using the distributed beam design method.

Pennoni, the Project Engineer, and DelDOT selected a geopolymer lining as it required only a small construction footprint and provided a fully stand alone, thin structural liner that is soil tight, corrosion and scour resistant without cold joints and environmentally friendly. Filling the corrugations improved hydraulic performance and water could be managed with an internal bypass. It was also the most economical option.

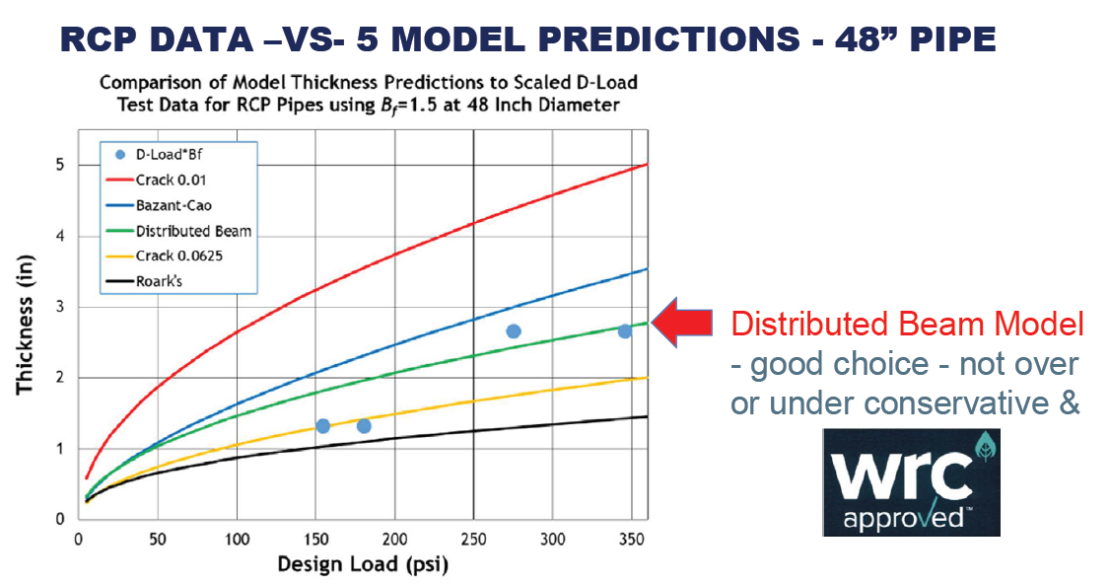

Getting concurrence on selecting and specifying a spray-applied liner design methodology is a challenge as there is not currently a specific ASTM design method that everyone is adhering to. Selecting one is necessary so that all bidders will be providing equivalent load bearing designs. The distributed beam design methodology was chosen as it was approved by the Water Research Centre (WRc), based on prior research: ‘Laboratory testing and analysis of geopolymer pipe-lining technology for the rehabilitation of sewer and stormwater conduits.’ The research shows the distributed beam to be a solid reasonable design method that is not too under or over conservative. See figure 2.

The design assumed the existing pipes were fully deteriorated and utilized the distributed beam liner design method requiring an unreinforced geopolymer mortar liner ranging from 2.4 to 3.2 inches thick. This created a corrosion resistant, unreinforced structurally independent, new pipe inside the old pipe structure expected to last 70 to 100 years.

To meet the strict deadline, JJID, the general contractor, coordinated three working crews at the different locations with the project taking an average of 17 days per location to complete. JJID managed the internal and external bypass and their trenchless pipe rehabilitation lining subcontractor, EN-TECH Corp, was responsible for shotcrete hand application of the geopolymer mortar.

Fortunately, JJID only had to manage the normal dry weather flow because when a storm came up, the lining contractor could easily stop their shotcrete application and permit the storm to pass.

The project included:

- Pre-Inspection and CCTV, Cleaning, Stopping Infiltration and Surface Preparation: After initial pipe cleaning and inspection, a minimum 3,500 psi pressure wash was used to remove loose debris. Joint leakage and infiltration was treated with grout. Piano wire was attached at the proper offset for thickness control.

- Geopolymer application: to install the Geopolymer Lining System the applicator used 50-pound bags of dry geopolymer material blended with a 20% maximum water ratio at the mixer. The GLS can be centrifugally spin cast onto the host pipe, however the applicator chose to install the GLS by hand shotcrete spray application. It was given a broom finish surface.

- Quality Assurance (QA): 28-day compression and flexural strength tests were also performed internally by DelDOT.

- Post Inspection and CCTV: At the conclusion of the project, the Contractor provided a detailed Quality Assurance/Quality Control (QA/QC) report with the Pre and Post inspections and QA material test results.