United Kingdom

AVT EZ Valve Installation Summary

- 8” carbon steel sea water storage tank.

- Old, seized valve meant no control point was operational.

- Team of two AVT EZ Valve experts completed the install in two hours.

When vital refurbishment work was required on a 1 million+ gallon sea water storage tank that feeds a fire system, engineers realized the valve which should isolate the tank from the remainder of the fire system, was seized and could not be closed.

The operators of the UK refinery needed a way to install a valve without shutting off the water supply that the plant relies on for its fire protection. Having, for several years, worked with the professionals from CSNRI who had resolved various issued using their range of engineered composite systems, they turned to the team for support. CSNRI immediately recommended they use partner company Advanced Valve Technologies’ insertion valve.

The AVT EZ Valve, a valve which can be installed without the need to shut off the water, has been used widely across the U.K. and U.S. within water authority systems but its installation in industrial applications in the U.K. is, so far, limited.

Once the decision was made that the EZ Valve would be able to resolve the issue, the team at CSNRI contacted their Advanced Valve Technologies colleagues who would carry out the install, Regional Account Director Jason Taylor, and Engineering Manager Lee Kirkham.

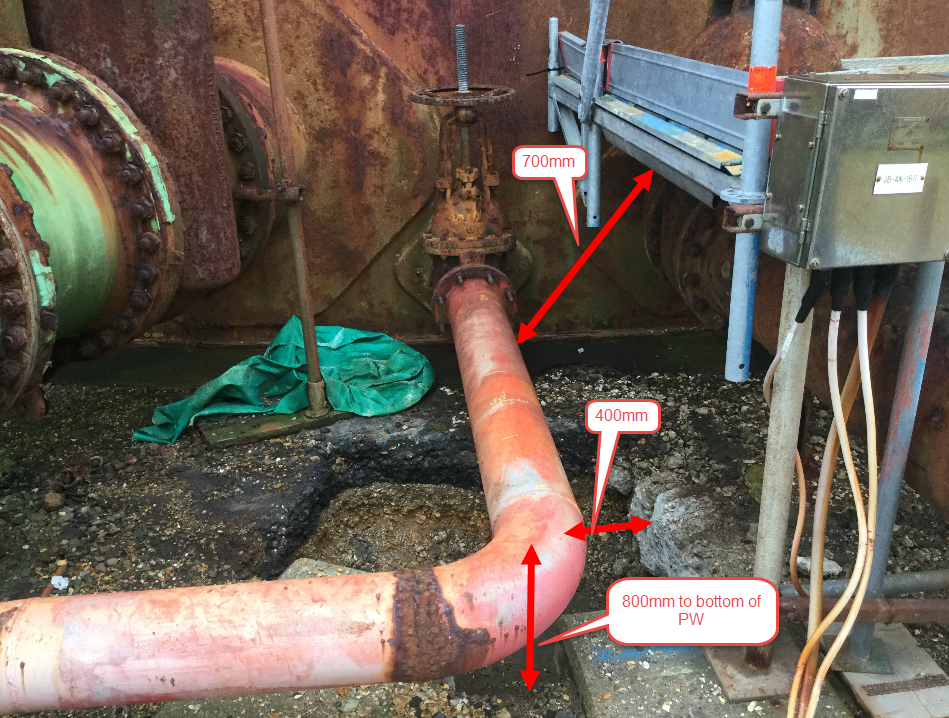

The 8” valve was installed on an exposed carbon steel line in a relatively cramped area. The EZ Valve is installed using a low-profile EM (End Milling) machine which mills a 120o slot across the top of the pipe and enables a resilient wedge gate to be inserted. The millings created, or swarf, is flushed out of the valve during the milling process by the pressure of the water in the pipe, meaning the quality of the water is maintained. This all takes place without the need to shut off the water and the small slot milled also ensures the integrity of the pipe is not affected. Jason and Lee completed the install within just two hours.

CSNRI’s UK Managing Director Sean Connolly said: “CSNRI and AVT deliver very different product ranges but both work within critical infrastructure. We are all aware of the range of products available so when we identified the need for a new valve at one of our customers’ plant we know the EZ Valve would be the ideal solution. We are delighted we were able to introduce our AVT colleagues to the customer and that the install went so smoothly.”