Stress Engineering tests determine greater resistance capacity and enhanced pipeline protection

Houston (July 12, 2017) - Clock Spring Company, LP (Clock Spring), the world’s leading manufacturer of permanent and temporary composite pipeline and pipe work repair solutions, today announced the results of Stress Engineering Services, Inc.’s (Stress Engineering) full-scale upper-bound shear testing, validating the stronger capacities of the Clock Spring Casing Spacers product. Clock Spring contracted with Stress Engineering to perform the shear tests on its derivative casing spacers product, evaluating and comparing Clock Spring performance against traditional casing centralizer and spacing solutions.

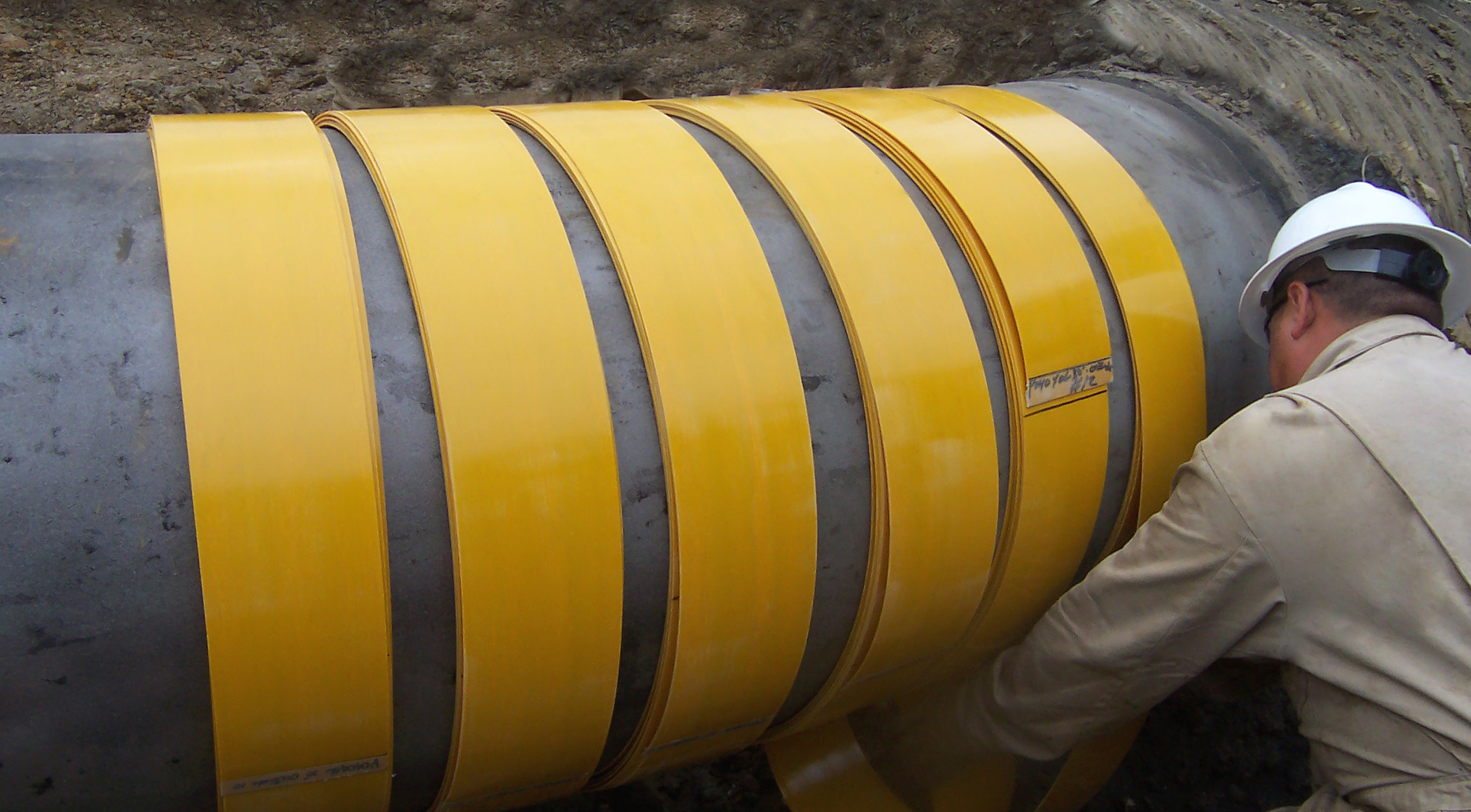

Contractors and operators install casing spacers and centralizers on carrier pipes to protect pipe integrity. They prevent contact between the carrier pipe and casing, minimizing coating damage and during construction and ensuring centralization when construction is complete. The casing acts as a storage vessel to limit the environmental impact in the unlikely event of a leak and can help protect pipelines against third party interference and damage.

The most commonly used casing spacers are bolt-on devices made of plastic or steel. Other common casing spacers are banded wood skids. Unfortunately, while the theory behind these solutions are sound, the bolts and bands often break or move when crews pull or push carrier pipe through casings. This results in coating damage and also can cause the installed pipe to rest in contact with the casing, which can more quickly lead to corrosion and carrier pipe weakness.

Stress Engineering Services performed shear tests to measure the likelihood of a casing spacer breaking or dislodging during the application of axial force to the pipe and the spacers. The tests compared the Clock Spring solution to traditional bolted solutions by applying concentric and eccentric shear to spacers installed on abrasion resistant outer coating (ARO) coated steel and PVC pipes. The testing force required to initiate sliding of the Clock Spring solution was approximately 19 times greater than traditional casing spacers and five times harder to keep them moving. A white paper detailing these dramatic results is available here: Clock Spring Casing Spacer White Paper.

“Axial shear resistance is an important variable and determines the maximum amount of force that can be applied to a spacer before it begins to slide,” said Buddy Powers, Vice President, Product Management and Technical Services. “Needless to say, we couldn’t be happier with the results.”

“We are driving innovation to enhance safety and provide stewardship of customer assets and the environment,” said Matt Boucher, Clock Spring President and Chief Executive Officer. “These encouraging results about this easy to install product are greatly gratifying and further validation that we’re on the right track.”