Baton Rouge, LA

Summary

- Faltering 40-year-old booster pump servicing hospital

- 6” galvanized pipe, 9’ in the air

- Valve fit upside down to cater for awkward position

When a 40-year-old booster pump servicing Ochsner Health Centre in Baton Rouge, La began to falter, officials knew that had to resolve the issue fast. COVID-19 had left the hospital at full capacity so turning off the facility’s water was not an option. The pump’s existing control point was inoperable, so a new valve needed to be installed.

The officials turned to new AVT partners Steam & Process Repairs who weighed up the different options of installing a valve on the system. Freezing the line, using a balloon stop or a stopple meant a traditional valve would still need to be fit, but since the AVT EZ Valve can be installed without having to shut off the water it would halve the labor time for this job. Despite being a new partner of AVT, Steam & Process Repairs had been learning about the product and was confident that the EZ Valve was the right option for the job.

The company accessed AVT’s efficient installer training program and took its operatives through the online curriculum section of the training before getting hands-on experience during the install at the health center. With AVT technical experts on hand, the team of four Steam & Process Repairs installers took just three hours to complete the install. This was an impressive feat considering the location of the line that required the valve.

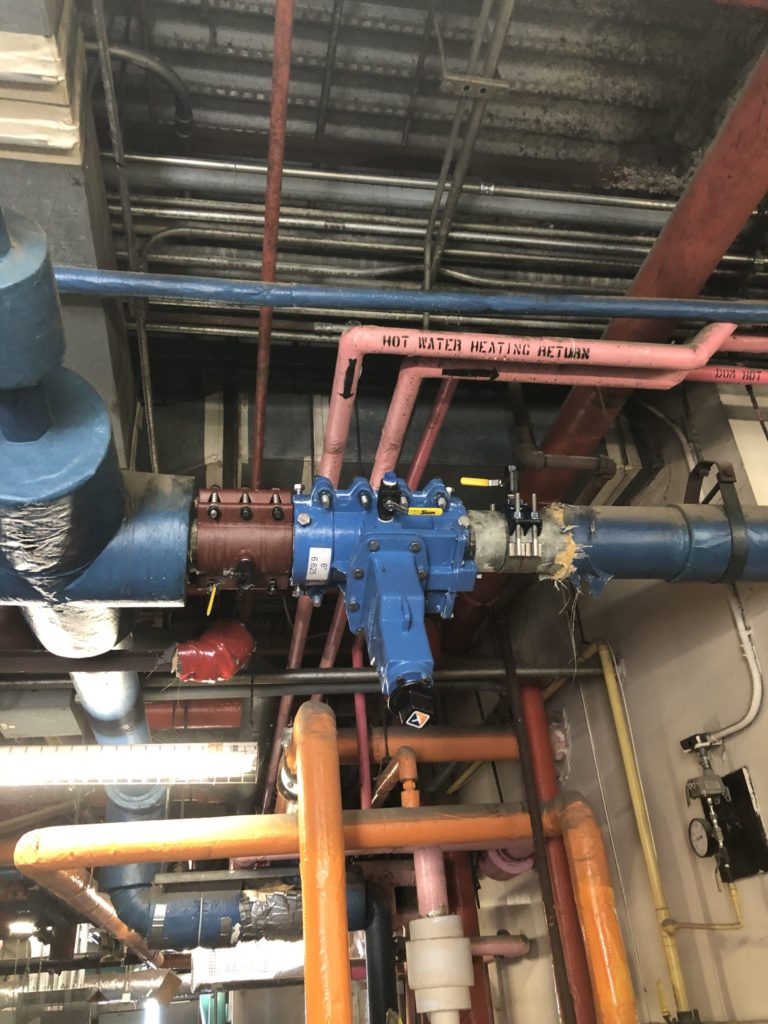

The pipe was a 6” galvanized chilled water line that hung 9’ in the air near the ceiling of the hospital’s mechanical room. Its location also meant the AVT EZ valve would need to be installed upside down.

The EZ Valve is installed using a lightweight toolkit, which includes an EM (end milling) machine that is used to create a small 120o slot in the water pipe enabling the resilient wedge gate, that forms the water stop, to be placed into the pipe. This easy-to-maneuver equipment meant the awkward position of the valve’s install location was not a challenge.

AVT’s Sales Director Shawn Petty said: “We know that what we do matters, and this has never been demonstrated so clearly than with this install. The hospital relies on water and we are proud that our EZ valve enabled the facility to keep running while the team at Steam & Process Repair installed the valve and carried out the repair to the pump.

“We are excited to have built a new partnership with Steam & Process Repairs and look forward to working with them in the future.”