WATER/WASTEWATER

PROJECT OVERVIEW

The Dewey Plant has been producing textile chemicals, colorants and other specialty compounds since 1969, and the plant has been expanded several times over that same period. The facility has a series of chemical sewers that collect and direct waste chemical solutions for treatment and processing. In 2000, the plant installed HDPE piping as a repair mechanism for many of these sewer lines.

Unfortunately, the high temperatures (200F+) of the industrial waste that enters these sewers caused the HDPE pipes and manhole liners to expand and contract, causing potential environmental concerns. The plant was looking to repair the system, prevent the HDPE from expanding and ensure ongoing proper environmental controls.

SOLUTION

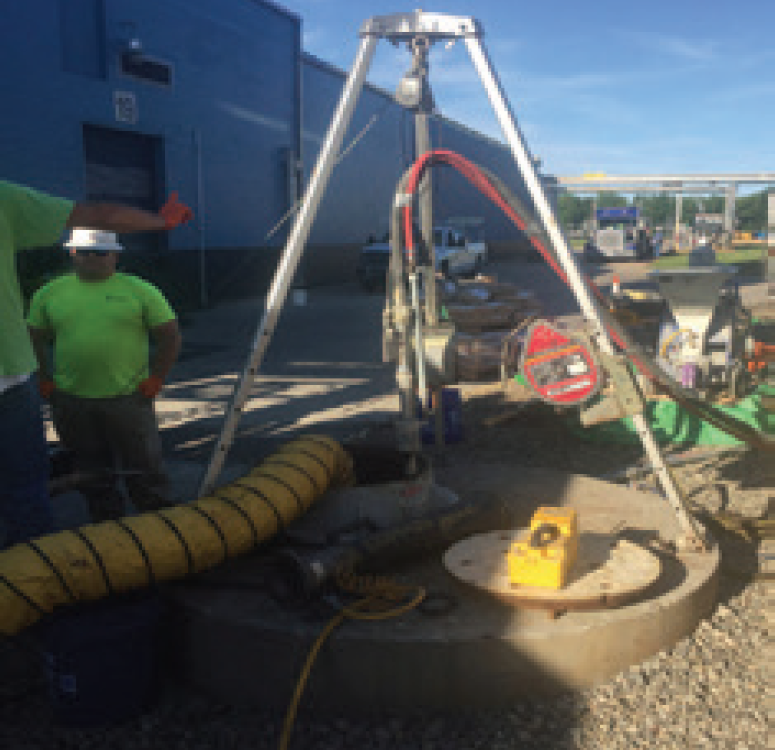

TIn 2016, the plant began the combined UV and glass reinforced pipe (GRP) rehab and GeoSpray mortar projects in two phases. In the first stage, two 12 -inch pipes of approximately 300 feet in combined length were lined with a glass reinforced, UV-cured felt liner. Additionally, GeoSpray mortar was applied in one 60” x 96” manhole. The objectives were to place the two rehab materials into hostile operating conditions for a monitoring period and to isolate and prevent expansion of the existing HDPE network. After the UV GRP materials were carefully installed and fully cured, the manhole was steamcleaned and coated with GeoSpray to effectively seal the system.

Production for Stage 2 began in June 2017. Upon inspection of the UV GRP liners and GeoSpray, it was clear that both solutions had performed very well and the decision was made to completely rehab the existing HDPE waste system. During the next 45 days, more than 1,700 linear feet of 12”- 36” HDPE pipe were lined, and 19 manholes were cleaned and coated with GeoSpray geopolymer.

“Engineered Lining Systems, in cooperation with 3R, did an excellent job and worked well with each other to complete the project on time. I would highly recommend the use of these two companies in any future pipe cleaning, pipelining or coating projects at other plants. This team worked together to bring this project in on time and on budget with no safety or environmental issues,” said Michael Thomas, Senior Production/Process Improvement Technologist at Milliken Chemical.

RESULTS

The installation of the UV GRP liners and the coating of all the affected manholes were completed over a 45-day period. The Dewey plant remained open the entire time at full production levels. The facility now has a safety sealed chemical sewer that is resistant to the extreme temperatures often seen during plant operation.

PROJECT DETAILS

Application: Manhole Rehabilitation

Client: Milliken Chemical

Location: Inman, SC

Installation: November 2017

Installer: Engineered Lining Systems