West Africa

Pipe Details

-

102-mm (4-in) diameter pipe experienced internal erosion that resulted in a through-wall defect

-

8.56 mm (0.34 in) original wall thickness.

Summary

- 102-mm (4-in) diameter pipe experienced internal erosion that resulted in a through-wall defect

- Two CSNRI trained technicians completed the 8-layer composite repair in 2 days

- No hot work was required during the repair application

- Operations resumed safely until a permanent repair could be executed

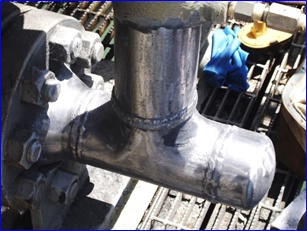

Internal erosion on a 102-mm (4-in) diameter cushion T on an offshore facility had resulted in a through-wall defect that required immediate attention to minimize environmental impact and return the line to service. The asset owner shut in production to isolate the line but was unable to address the defect using traditional repair methods to restore the line to safety.

What was needed was a temporary reinforcement leak repair that would allow operations to continue safely until a spool section could be fabricated and the line replaced.

The answer to this challenge was CSNRI Contour (now ThermoWrap). Because the repair would have to be made on a line carrying hydrocarbons, engineers designed the solution in accordance with ISO 24817, which gives requirements and recommendations for the qualification, design, installation, testing and inspection for externally applied composite repair systems to corroded or damaged pipework, pipelines, tanks and vessels used in the petroleum, petrochemical and natural gas industries.

The repair team executed the composite installation on the spool sections. The first step was to clean the spool section using power tools to remove the coating before applying a bristle blaster to create an adequate surface profile equivalent to SA2/NACE#3 so the composite repair could be installed.

The team of 2 technicians completed the repair over the course of 2 days following standard installation procedures, restoring the integrity of the line without introducing additional risks, allowing regular operations to resume.