Composite technologies are changing the way corrosion repairs are carried out on offshore assets. Though there has been slow adoption of this technology in the energy industry, it is a proven alternative that merits further examination. Composites have been used to repair a range of offshore defects, producing positive results that prove they can compete directly with traditional repair techniques to extend the service life of this critical infrastructure.

CONTENDING WITH CORROSION

Offshore assets are exposed to an extremely corrosive environment. The seawater/air creates an environment that is even more corrosive than conditions beneath the surface. Although, marine coatings provide excellent corrosion protection, when exposed to this environment over time they can fail. Corrosion can lead to damage, structural failure, lost production, and in extreme conditions, environmental incidents. To date, the common repair option has been limited to removing damaged sections of pipe and replacing with new spool pieces, which introduces a range of safety risks associated with heavy lifting and welding. These activities also require a weather window for safe execution, and production must be shut in while the repair is being carried out, which can escalate costs.

Composites were developed specifically to contend with corrosion. In general terms, a composite combines two or more materials, a high-strength reinforcement in fibrous form, incorporated into and bonded by a matrix, usually a thermosetting polymer. The most common strength component is glass.

Most glass fibers consist of E-glass, a term that derived from the words “electrical grade glass.” This super-cooled mixture of metallic oxides is brittle and transparent but has very high tensile strength, 500 ksi (3,400 MPa). Glass is produced in a furnace at about 2,192°F (1,200oC) and spun into fibers of approximately 10 microns in diameter by allowing it to drain under its own weight through many heated bushings.

When engineers are designing a composite, they focus on three characteristics:

• Fiber type: glass, carbon, or aramid (strong, heat-resistant synthetic fibers frequently used in aerospace and military applications)

• Fiber form (typically roving, tow, mat, or woven fabric)

• Fiber orientation or architecture (Reinforcement can be oriented in any direction the designer desires. The most common structural elements are designed with greater strength in the direction subjected to the greatest load.

CONSIDERING THE OPTIONS

It is important to distinguish among the composite repair offerings on the market because not all composites are equal. The distinctions can be critical specific to the particular repair applications, so it is important to understand how composite repairs differ.

Any composite repair being considered for an offshore application should be:

• Non-intrusive, limited disruption to normal production

• Suitable for in-service applications

• Permanent, restores the serviceability to the pipe beyond its design life

• Cost effective

• Fully predictable and verifiable by modeling and/or definitive equations found in current design standards

• Able to eliminate all installation variables

• Eective in all locations and environments

• Eective for all pipe grades and sizes

• Designed to meet or exceed current code requirements.

• Formulated and constructed to eliminate field design and field engineering

• Able to conservatively restore the pipe to its original strength

• Rigorously tested and subjected to peer review

• Field proven.

A composite that will work in an offshore environment must be designed carefully to ensure the mechanical properties can provide the necessary strength to restore the line to the appropriate level of operation, typically to its original design standard. With the proper repair designed, installation procedures must provide the permanency required of the repair. This means the composite repair, when completed, must be able to compete with traditional repair alternatives in terms of safety, economics, control of installation variables and effectiveness.

To be reliable and predictable, a composite should be manufactured under controlled conditions. Manufacturing material in a facility allows accurate control of the ratio of glass to resin under conditions that can be monitored. Within a facility, the unidirectional glass strands can be carefully positioned, pre-tensioned and aligned to maximize strength, and the composite can be compressed, dried, heat-treated, cured, and inspected before being shipped as a completed unit to the repair location. This approach allows design variables to be controlled by the manufacturer, producing repair units that are consistent and documented. Regardless of the manufacturing process and its location, a quality composite requires that the reinforcement be completely saturated with the resin. The composite also must be compacted to squeeze out air bubbles and excess resin and be fully cured before it is suitable for carrying loads. In a factory environment, quality control procedures can deliver these properties more consistently in the finished product than can be achieved in field applications. Without this predictable performance, long-term durability would be questionable.

The composite laminate layers produced by Clock Spring are nominally 0.065-in. (1.65 mm) thick and have a glass fiber content ranging from 60% to 70% by weight (45% to 55% by volume). The resulting material exhibits linear elastic behavior up to the point of failure in tension, typically 1.5% to 2% strain. Elastic modulus values are 5 by 106 psi (0.34 by 7.3 bar) in the fiber direction and 1.4 by 106 psi (0.09 by 7.3 bar) in the transverse direction, with tensile strength in the range of 75-100 ksi (517-690 MPa).

It is important to understand the structure and application of a composite material to gauge its suitability for a particular repair. Composites can fail in three areas: the fibers, shear/laminate bonds, and interface failures between the resin and the fiber. In addition, the composite repair is also susceptible to degradation overtime due to moisture absorption, temperature fluctuations, and fatigue. Uniaxial fibers oriented and protected by “size” that is specially designed and heated to promote bonding of the fiber, size, and resin prevent degradation, delivering a much stronger and longer-lasting composite. These fabrication risks are best managed in a controlled manufacturing environment. Wet wraps applied in the field contend with many variables that can be eliminated in a properly managed facility.

COMPOSITE REPAIR

Composite repairs reinforce the damaged section of the substrate by wrapping the defect area with a composite sleeve that shares the hoop load, reducing the stresses in the pipe wall. The hoop load must be efficiently transferred to the composite for the appropriate load sharing to be achieved. The only way to accomplish this is to fill external defects with a high-compressive strength material that protects the thinned ligament from further yield.

This can be designed into the repair system by using unidirectional rovings or woven cloth as the reinforcing element. Unidirectional rovings provide more strength than woven cloth for the same ratio of glass to resin and are less prone to damage caused by cyclical loading. Unidirectional E-glass embedded in a polyester resin provides the best method for high- pressure reinforcement. This part of the repair is crucial because it re-establishes the strength of the pipe, delivering performance that exceeds the “as new” condition. Repair techniques that do not use filler are unsuitable for critical high-pressure repairs. While relatively new to the offshore arena, fiberglass composite repair sleeves have a long track record in other industries.

Building a better composite

Creating a composite that can withstand harsh environments and high pressures requires engineering that factors site conditions into the formula of the composite. The Clock Spring repair sleeve is a fiberglass composite that has a memory, created by a manufacturing method that constrains its cylindrical shape over several concentric layers, similar to the winding spring of a clock or watch. The glass fibers in the composite wrap are continuous and are aligned circumferentially to maximize the composite strength. When the sleeve is installed on a pipeline with the proper adhesive, the resulting structure provides circumferential reinforcement of the defect and reduces the hoop stress of the steel pipe under the wrap.

This three-part system comprises a unique unidirectional composite structure of glass fibers and polymer base, a patented two-part adhesive system, and a proprietary high-compressive strength load transferring compound.

Two application techniques are available for the repair of both low- and high-pressure systems: full-cure and wet wrap. In the full-cure process, the composite sleeve is completely cured in the manufacturing facility and installed using filler and adhesive in the field. The composite sleeve is coiled slightly smaller than the outside diameter of the pipe and cut to the length required by the repair. This method allows the glass direction and composition to be fully controlled. Wet- wrap requires that the glass cloth be wetted with resin in the field and applied to the pipe in the wet condition. The amount or length of the wrap is variable and determined in the field. Curing takes place as part of the installation process.

A typical repair consists of locating and cleaning the damaged area. Filling the defect and other voids under the repair with a high compressive strength filler material to transfer the loads from the pipe to the externally applied composite sleeve. Using adhesive to secure the composite to the pipe, and keeping the repair under tension while it cures to force excess adhesive and filler out the edge of the unit ensures a fully filled, tight fit. Installation takes approximately 30 minutes, and the repair cures in about two hours.

Several factors make the full-cure composite sleeve installation process more desirable than the wet-wrap process. The full-cure application process eliminates the wet-wrap variables of wrap tension, glass alignment, resin saturation, composite length and the installation variables caused by field conditions. The mechanical properties of the full-cure wrap are more consistent and better defined than those of the wet-wrap.

COMPOSITES IN ACTION

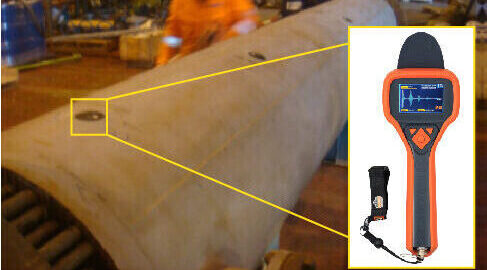

Composites have been applied to a range of offshore repairs. In one case, ultrasonic tests revealed several severe internal defects in a 16-in. (406-mm) pipeline running into the main high-pressure separator on a production facility offshore West Africa. The erosion was significant, affecting multiple places along the pipe and growing at such a rate that imminent failure was likely. If the damage were to reach a critical point, the platform would have to be shut in, resulting in a huge loss of production. In addition to the financial impact, there was potential for considerable environmental impact in the event that the eroded pipe developed a leak.

The operator needed a way to reinforce the pipe without halting production. The goal was to find a safe and reliable repair that would allow the line to function safely until the next planned shutdown, nearly a year away.

A Clock Spring Contour repair was designed for the offshore asset in accordance with ISO 24817 2015 guidelines, which provide requirements and recommendations for qualifying, designing, installing, testing, and inspecting the external application of composite repair systems to corroded or damaged pipework, pipelines, tanks, and vessels used in the petroleum, petrochemical, and natural gas industries.

A team of trained technicians cleaned the section of damaged line using power tools to remove the external coating and then bristle blasted it to create a surface profile equivalent to SA2.5 (which requires cleaning to remove all rust, coating, and mill scale to produce a near-white surface) before applying the adhesive, placing the repair unit and putting it under compression, and allowing it to cure to permanency. With the repair completed, the platform continued to operate without incident until the planned shutdown 12 months later, when the damaged section was scheduled to be replaced.

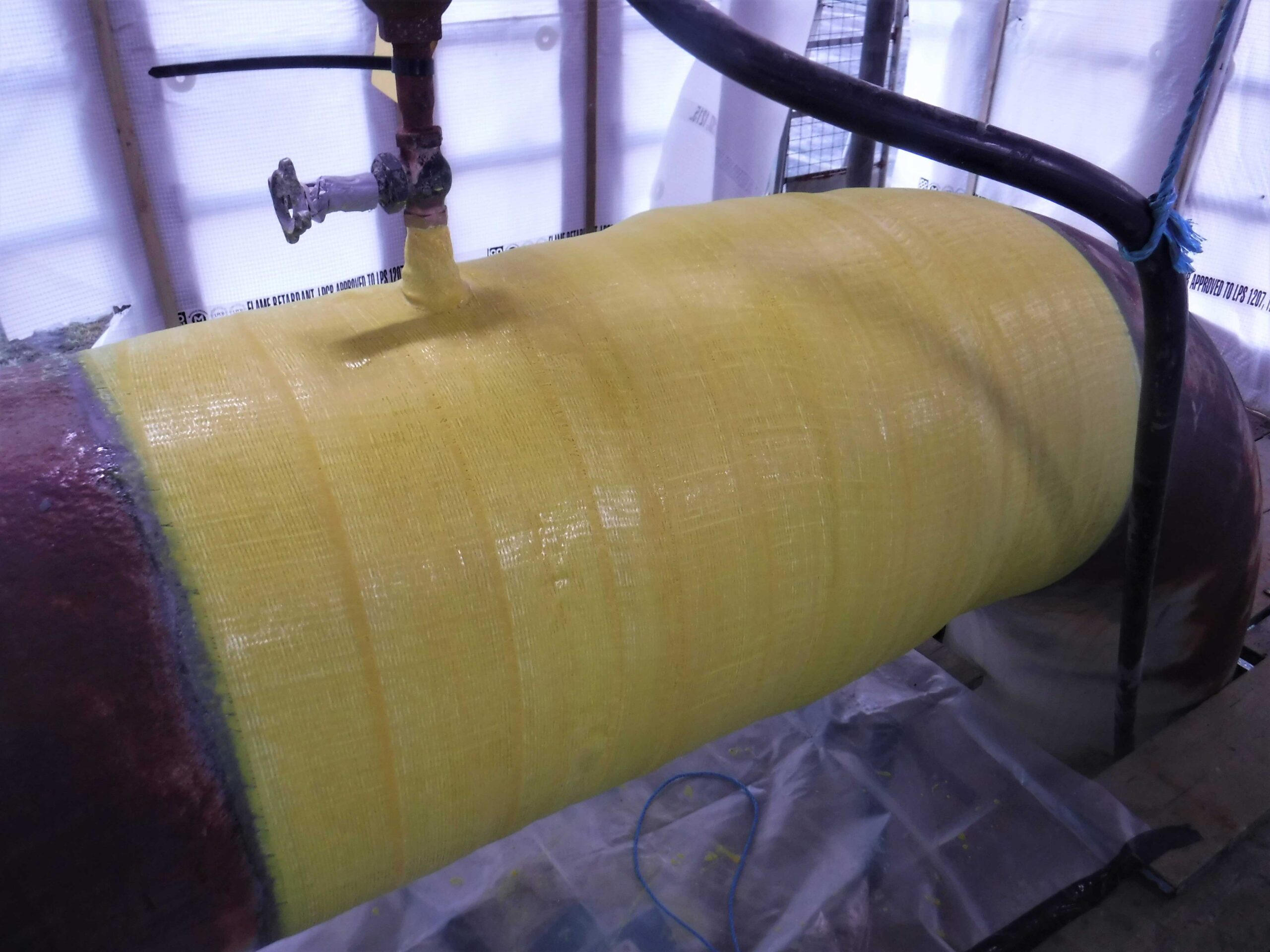

In another instance, an operator offshore Malaysia discovered extensive pitting in a 12-in. (305- mm) riser with back-to-back bends while conducting a riser inspection on an offshore production facility. In some portions of the pipe, pitting had resulted in 60% wall loss. It was imperative to repair the line quickly without disrupting production, so the company chose to address the problem with a composite repair.

A team of specially trained local experts cleaned the riser, grit-blasting it to an SA 2.5 surface prior to applying the composite repair. Once the area was thoroughly cleaned, repair technicians identified the defects and marked them so they could be appropriately treated. The defects, which were concentrated at the bends, were first repaired with 3-in. (76-mm) wide Snap Wrap strips along a 6-ft (1.8-m) length of pipe.

In cases like this, where Snap Wrap applied around pipe bends is placed with spacing that exceeds 0.5 in. (13 mm), the repair is overlaid by a Clock Spring Contour system. In this application, Contour overwrapped the entire 16.4-ft (5-m) length of the repair to create a solid covering. This hybrid system of prefabricated sleeves and in-the-field cured composite repair merges a robust structural laminate with a exible protective outer composite jacket. The repair is designed to last for two decades.

This was a rapidly executed repair, performed in a day and a half of on-site work. A small team carried out the repair with minimal disruption to daily activities and without taking the riser out of service.

Composites compete under water

Composites are suitable for a broad range of applications, but there are some conditions in which they are not an appropriate repair solution. Composites are unsuitable for situations where the surface cannot be properly prepared, which would lead to issues with bonding or sealing, and they cannot be applied on concrete.

They can, however, be used on condensing pipes and in a range of conditions, including under water to depths of 30 ft, which makes them appropriate for installations that heretofore have been carried out by underwater welders.

Traditionally, welding below the water line is either dry, also called hyperbaric welding, or wet. Dry welding requires a structure to be built around the weld area so water can be pumped out to create a dry environment. The area can be small (conned to the damaged area) or large enough for the welder to physically enter. For large areas, oxygen is pumped out of the enclosure, and helium is pumped in. Wet welding, because it is done in the water, introduces the need for a diver properly outfitted with diving equipment, which means it introduces the risks associated with diving. Electric shock is another risk, as is the possibility of explosion if the welding process is not well controlled.

Because hyperbaric welding is better controlled, it produces a more reliable weld than underwater welding. The problem is that environmental conditions are not always conducive to dry welding. And many owners are not comfortable with the risks – both personal and structural – inherent to wet welding.

A repair sleeve can be placed using a special underwater adhesive. The repair, which can be carried out by a trained diver, is relatively straightforward, following the same approach as a repair in dry conditions. Because this approach requires no construction or complex installations to create a dry environment, a composite repair can produce a lasting repair without any hot work. This capability introduces a new alternative for underwater line repair.

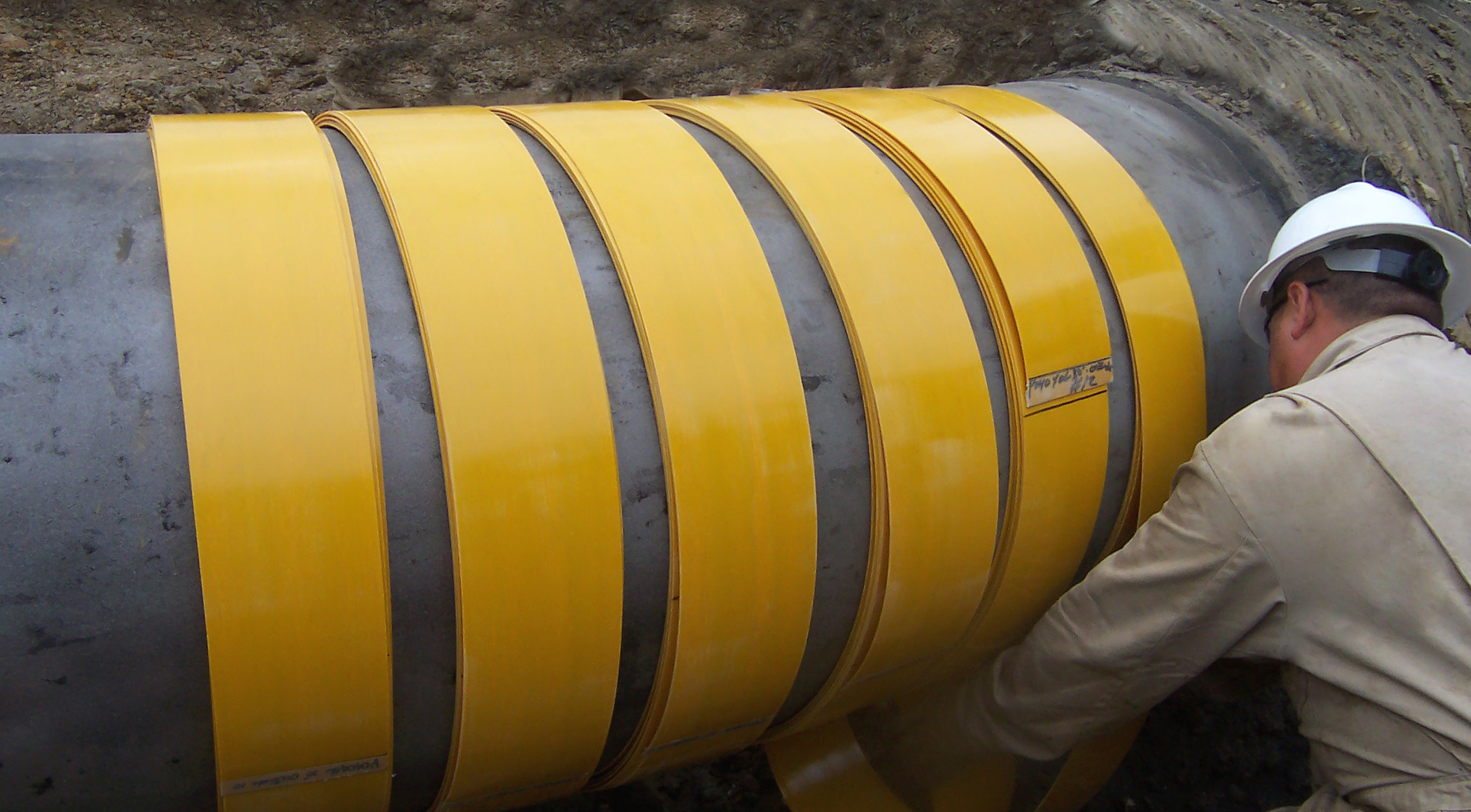

On another asset in the Middle East, corrosion was identified on the riser support clamps that secured the production risers to the hull. The 14-in. (610-mm) heavy wall structural cross member was damaged across a length of 26.25 ft (8 m). Severe external corrosion, which in some cases amounted to 80% metal loss on the structural member designed to hold the riser support clamps, was jeopardizing the safety of hydrocarbon production. The company needed a solution that could be carried out offshore in a short time frame with little disruption to its operations.

Performing the repair required the construction of an engineered heavy-wall composite sleeve, manufactured in 24-in. (600 mm) widths using bi-axial glass architecture. The specialized solution produced extended sleeves that would cover a longer length of pipe than a traditional repair.

A trained and certified team of installers applied extensive filler and molding to rebuild the pipe surface to the original outer diameter and installed the sleeves cut to length in a brick wall fashion.

When the repairs were completed, the riser holding clamps were put back into service. This repair averted an incident and allowed the production platform to safely continue operations both during and following the repair.

LOOKING AHEAD

Composite repairs have become more common on offshore energy assets because they are safe, effective, and relatively simple to execute. While they are newly being considered on a larger scale for offshore applications, they have a long track record of successful application in other industries. Today’s composites are the result of a years of engineering efforts and extensive testing that have resulted in a cost-effective and expedient alternative that eliminates heavy lifting and hot work, delivering effective and long-lasting repairs.

The successful execution of a range of composite repairs illustrates the viability of composite solutions for oshore energy assets. The ease, speed, and effectiveness of composite repairs have the potential to dramatically change the way owners and operators contend with corrosion and extend production life on oshore assets.