Industries

Applications

Crack Repair with Composites

With increasing testing and design capabilities, composite repairs can successfully help remediate crack-like features and provide owners/operators a reliable tool in crack repair. Learn more here.

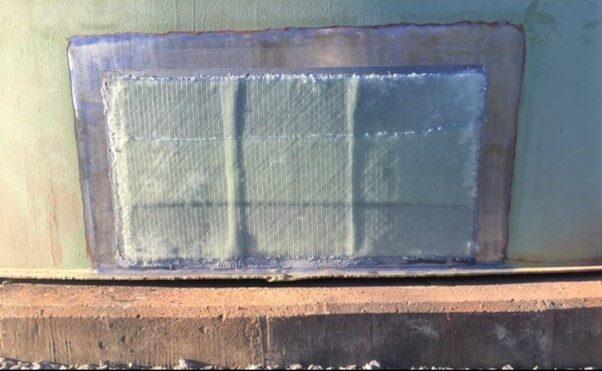

Tank Repair with Composites

Traditionally, composite repairs have been used on repairing round, pressure containing pipes with high degrees of success. But, composite repairs can also be installed as patches on large storage tanks to remediate defects.

Learn more here.

Offshore Repair with Composites

CSNRI has continued to work closely with the offshore industry to test and validate the use of composite repairs in the harsh and corrosive offshore environment. Learn more here.

HDD & Trenchless Protection with ScarGuard

CSNRI's ScarGuard has been tested and proven against some of the most common and aggressive, defect-causing issues in HDD and similar trenchless technologies installations. Learn more here.

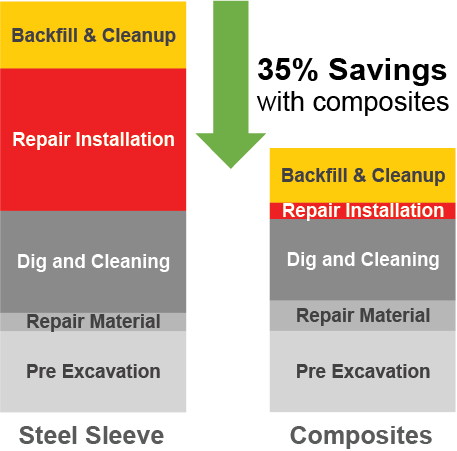

Composite Repairs vs Steel Sleeves

Discover how composite repairs can offer a cost-effective solution, cutting your maintenance expenses through safer, simpler, and quicker installations.

Learn more here.

Case Studies

- A+ Wrap Is the Perfect Solution for Pipe Corrosion in Fluctuating Dry and Wet Environments

- A+ Wrap™ Repaired Corroded Offshore Riser

- AcidShield Restores Original Design Strength to MIC-Damaged Pipe at Chile Refinery

- Atlas Permanently Reinforces Seam Weld Anomaly on 16” Ethylene Line

- Atlas Provides Quick Dent Repair Solution for Liquids Pipeline

- Atlas Reinforces LF-ERW Seam Anomaly on Ethylene Line

- Atlas Repair of Complex Air Interface Process Lines Remediates External Corrosion

- BlackDiamond® 12" Dent/Gouge Repair in USA

- BlackDiamond® Restores 36-inch Gas Pipeline

- Casing Spacer Axial Shear Testing Results Validate Better Product Performance

- Clock Spring Composite Sleeve Repairs Wall-Thinned Pipe

- Clock Spring Provides Permanent Repair to Damaged Refinery Pipeline

- Clock Spring Repair Targets Weakness in Pipeline Bends

- Clock Spring Repairs 24-inch Crude Oil Pipeline

- Clock Spring Repairs 42-inch Suction Line at Storage Terminal

- Clock Spring Repairs Damaged Girth Weld

- Clock Spring Repairs Dent Due to Rockfall in Hydro-Electric Pipeline

- Clock Spring Repairs Dent Under Water

- Clock Spring Repairs Mechanical Damage from Alkaline Soil Erosion

- Clock Spring Repairs Risers on Offshore Platform

- Clock Spring Repairs Seam Weld

- Clock Spring Restores Gouged Pipeline

- Clock Spring Takes on Onshore Refinery Repair

- Composite Addresses Internal Erosion on Offshore Production Unit

- Composite Contends with Arctic Conditions in Underwater Pipeline Repair

- Composite Corrects Internal Erosion Defect Offshore

- Composite Mends Pinhole Leak on a Topside Weldolet

- Composite Repair Addresses Galvanic Corrosion

- Composite Repair of a Vertical Knock-Out Drum

- Composite Repair Restores Lines Damaged by CUI

- Composite Repair Restores Offshore Firewater Line

- Composite Repair Takes on External Corrosion at a Chemicals Factory

- Composite Repairs 4-inch Prover Loop

- Composite Repairs with Embedded Thickness Monitoring Technology

- Composite Restores Wind Tower Flare Line Integrity

- Composite Safely Restores Leaking Valve

- Composite Solution Addresses Girth Weld Damage in High-Temperature Environment

- Composite Solution Fortifies New Construction Offshore

- Composite Solution Replaces Damaged Casing Spacers

- Composite Solution Restores Mitre Bend Integrity

- Composite Solution Restores Pipeline Explosion Damage

- Composite Solution Seals Crack in Gas Transmission Line

- Composites Enable Underwater Line Repair

- Composites Extend Service Life of Corroded Flare Line

- Composites Repair Topside Piping System Corrosion

- Composites Restore Offshore Riser Integrity

- Composites Take on Air-to-Soil Interface Corrosion on Gas

- Contour Achieves Pressure Containment, Reinforcement on 6-inch Kickback Line

- Contour Reinforces Corroded Cooling Water Line

- Contour Repairs Corrosion Under Insulation at a Gas Station

- Contour Repairs Internal Corrosion on Heat Exchanger

- Contour Repairs Leak Under Insulation in Ammonia Plant

- Contour Repairs Leaks in a Cooling Water Line

- Contour Repairs Nozzle on Thermal Oxidizer

- Contour Repairs Pinhole Leaks in Refinery Pipeline

- Contour Repairs Pitting on a Jetty

- Contour Restores Ammonia Tank Roof to Safety

- Contour Restores Gas Line for 20 More Years of Service

- Contour Restores High-Temperature Caustic Line

- Contour Restores Integrity to Platform Drain Line

- Contour Solves Corrosion Issue in High-Temperature Line

- Contour Strengthens Welded Joints for HDD

- Contour Tackles Complex Geometry on Ammonia Lines

- Contour Takes on External Erosion in Saudi Arabia Petrochemical Plant

- DiamondWrap® – 24″ Flare Line Repair in Saudi Arabia

- DiamondWrap® – Firewater Line Crack Repairs in Mexico

- DiamondWrap® 18″ Flare Line Repair in Singapore

- DiamondWrap® 4″ Internal Corrosion High Pressure Repair

- DiamondWrap® Delivers Temporary Repair for Internal Corrosion

- DiamondWrap® HTA™ 1″ – 16″ Odd Geometry Piping Repair in USA

- DiamondWrap® HTA™ 12″ – 42″ Flare Line Repair in Bahrain

- DiamondWrap® HTA™ 30″ Flare Line Rehabilitation in Kuwait

- DiamondWrap® HTA™ 80″ MDEA Pressure Vessel in USA

- DiamondWrap® MT Restores Bath Heater to Safe Service

- DiamondWrap® Riser Rehabilitation in Caribbean

- DiamondWrap® Tank External Corrosion Patch Repairs

- External Corrosion Repair on 36″ Nitrogen Plant Flare Line

- Failed Flange Welds Restored with ThermoWrap® MT Extending Service Life of Fire Main

- Lamination Repair on 12″ Liquids Pipeline in USA

- Leak Stopper, DiamondWrap® Restore Leaking Pipe to Safe Service

- Liquid Terminal Employs Composite Repairs to Restore Jetty Lines to Safety

- Offshore Composite Repair Strengthens Riser Supports

- Offshore HP Separator Leak Stopped with Contour

- Pipe Support Provides Rope Access Solution for Corrosion Repair and Pipe Protection

- Pipe Support, Anti-Corrosion Coating Improves Safety for New Pipeline

- ScarGuard® E Protects 56” Pipe in Saudi Arabia Microtunneling Application

- ScarGuard® Enables HDD Installation Under the Oneida River

- ScarGuard® Installed to Protect Subsea Pipeline

- ScarGuard® Protects Field Joint Coating During HDD

- ScarGuard® Protects Joint Casing System During HDD Installation

- SnapWrap Repair Halts Refinery Line Leak

- SnapWrap Restores Strength to Corroded Pipelines

- SynthoGlass XT Repairs Internal Corrosion on Cooling Water Line

- SynthoGlass® is at the Core of Maintaining Midwestern Utility Infrastructure

- Testing Validates the Use of Atlas for Restoration of Extensive Wall Loss

- ThermoWrap® MT Meets Challenge of Aging North Sea Pipeline System

- ThermoWrap® MT Repairs Corroded Vent Stacks Extending Service Life beyond Decommissioning Date

- ThermoWrap® MT Restores Crude Transport to West African Pipelines

- ThermoWrap® MT Restores Through-wall Defect in Complex Pipe Geometry Keeping Refinery Operating

- ThermoWrap™ MT Repairs Live Butane Line