EU

Summary

Billions of cubic meters of natural gas and petroleum are accessed through pipelines across the floor of the Mediterranean Sea each year. Pipeline owners are expanding multi-million-dollar systems to meet the growing energy needs of customers throughout the European Union. Laying pipe along the sea bed poses unique challenges. When laying sea bed pipe, external conditions, including salt water and abrasive movement, can result in erosion, corrosion, and consequently, a shortened pipe lifespan. In the eastern Mediterranean, a pipeline owner has taken preventative measures to ensure a new pipeline is protected as it was positioned on the sea bed. The pipeline owners chose ScarGuard® from CSNRI to protect their pipeline investment.

Benefits

- Non-shielding

- Superior mechanical protection

- Prevents gouging and coating damage

- Ensures future pipeline integrity

- Prevents future external corrosion

- High impact resistance

- No environmental hazards

- Easily installed over field- and factory-applied coatings

- Pre-impregnated, moisture-cured polyurethane resin eliminates field mixing or saturation

- Excellent abrasion resistance protects coated pipes in sea bed pipeline installation

Challenge

With two new pipelines being laid over two existing pipelines positioned on the sea bed in the eastern Mediterranean, pipeline owners chose to take preventative steps to protect the pipelines and joints at the overlap with a composite abrasion-resistant overcoat (ARO). In the areas where pipe crosses over pipe, movement can cause abrasion and other damage over time. Even more challenging was working in the time constraints required as pipe was assembled and welded on a continuously moving lay barge. The goal was to add a protective layer to areas of pipe as it was being laid, without any interruption to the process. These conditions required a product that could be applied and cured quickly in the limited workspace on the barge, as pipe came off the on-board assembly line. ScarGuard was chosen for the application, based on its proven protective performance, ease of application, and rapid curing properties.

Application

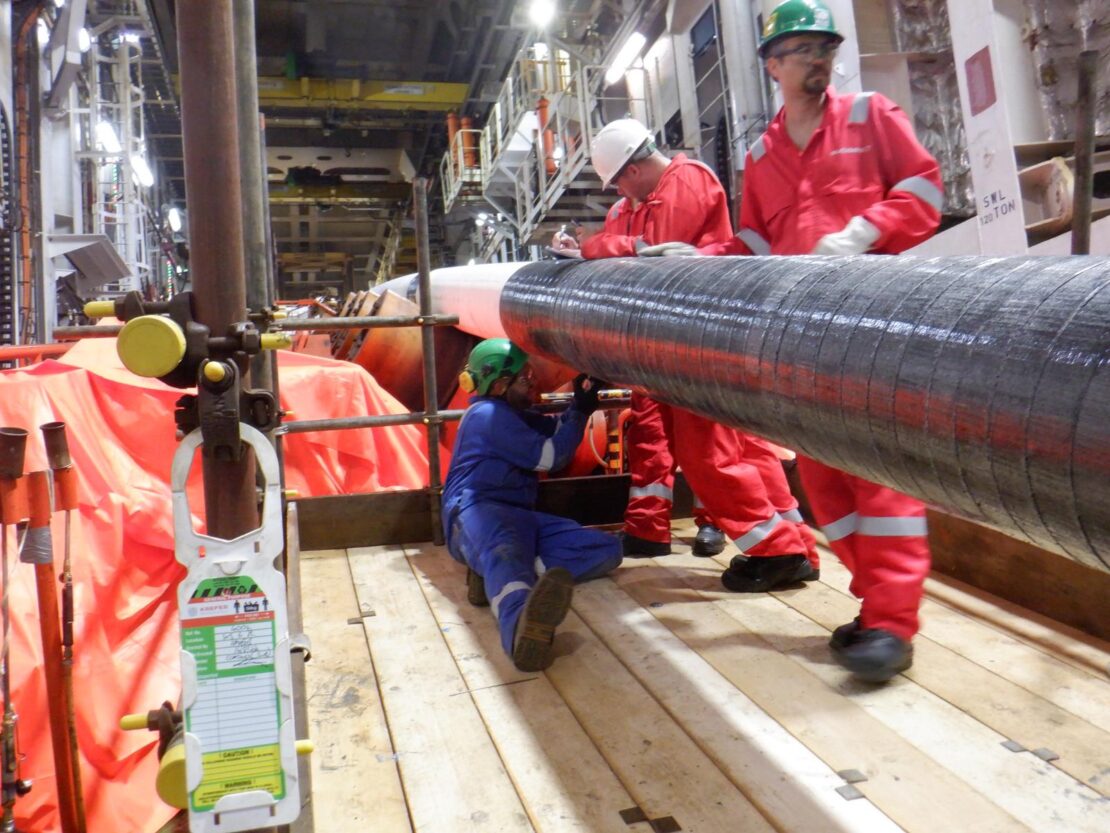

ScarGuard is designed to protect pipelines from corrosion, while also providing abrasion and impact resistance. Six expert CSNRI technicians from the UK were flown to the barge location to execute the ScarGuard installation. The system was specified as four layers of ScarGuard for a completed application thickness of 8 mm each for one 12-inch and one 16-inch pipe. The application had to be sited accurately on the two lengths of pipe, each 12 meters in length. Properly positioning the ScarGuard system was key to ensuring that, when laid, the wrapped section of each pipe would land in the correct position to cross over previously laid pipe.

It was critical that the ScarGuard system be applied and cured to the required hardness within a specified timeframe, as the barge continued moving forward and laying pipe. ScarGuard’s fiberglass fabric and pre-impregnated flexible resin is water-activated and cures within minutes. The system was installed quickly and cured as pipe continued off the barge, over the stinger, to be laid on the sea bed without any interruption in the ongoing pipe-laying process.

Results

This innovative approach to pipeline protection has been employed for less than five years. It has proven to be significantly more effective in protecting sea bed pipe than other coatings, which may become brittle or displaced over time, resulting in exposure to damaging conditions encountered when overlapping existing pipeline in the Mediterranean Sea. The application of ScarGuard at the time of pipe-laying protects against corrosion and abrasion that can lead to expensive, time-consuming repairs that could result in environmental concerns or interrupt pipeline operation.

The performance features of ScarGuard, and the ability of the CSNRI crew to apply the system quickly, allowed pipeline owners to stay on schedule. Achieving pipe protection in targeted areas while avoiding interruption of the pipe-laying process, which was critically important to the pipeline owners, allowed them to continue a $790,000-a-day operation seamlessly.