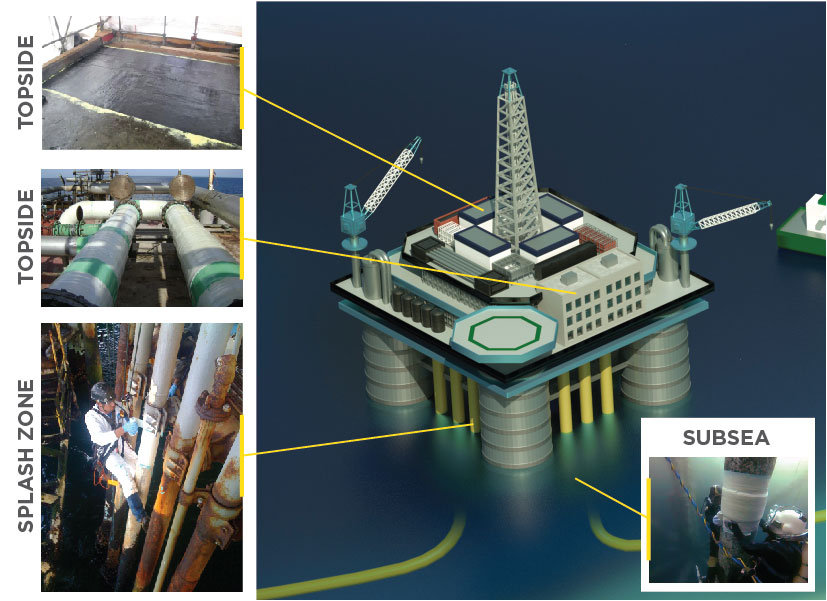

In the demanding environment of offshore platforms and rigs, having a rapid repair option for corroded or damaged piping is critical for safe and successful operation. Composite repair systems have been thoroughly tested by numerous organizations and programs over the years and are proven to be a robust, reliable, and effective method to repair, reinforce, and protect piping systems and pipelines. These offshore industry composite repair testing programs validate composites can be used for Topside, Splash Zone and Subsea applications. CSNRI has continued to work closely with the offshore industry to test and validate the use of composite repairs in the harsh and corrosive offshore environment.

Composites are the perfect solution for offshore repair

As with other oil and gas industry usage, composite repair systems can be successfully used for a variety of defect repair and structural strengthening, as well as for leak containment in through-wall situations.

While composite repairs can be used in Topside, Splash Zone, and Subsea areas, they can require variations in design requirements based on specific regulations, usage and/or client requirements. While Topside operates more like process piping systems or refineries, the Splash Zone and Subsea pipelines tend to operate more like onshore transmission pipelines from a requirements perspective. Implementation of a composite repair system in each of these locations requires further engineering design considerations.

Common uses for composites offshore

Composites are an ideal solution for many of the demanding offshore applications because they provide a lightweight, safe, easy to install, and cost effective to deploy solution.

In many instances, the installation team is dealing with hard to access areas which may require rope access or minimal scaffolding, making composites a perfect option. Typical defects range anywhere from mechanical damage (such as anchor drops on subsea lines), to general corrosion issues, to through-wall defects in Topside piping.

Composites as Pipe Protection

While composite systems provide efficient repair options, they are also ideally suited for protection of subsea pipe. A composite system applied for protective maintenance to new or existing lines can help guard against erosion and friction damage that can occur at points where pipe crosses over pipe on the sea bed. They can also provide protection for structural steel work on offshore platforms to prevent collision damage or damage from anchor strikes, thereby eliminating the need for repairs and possible downtime.

Common Repairs:

- Side hull

- Flare lines

- GRE Lines

- Caisson repairs

- Riser repairs

- Flare lines repairs

- CuNiFe line repairs

- Clamp locations

- Vessel repairs

- GRE lines

- Deck penetration

- Closed Drains

- Open Drains

- Calorifiers

- Water injection lines

- Produced water lines

- Produced Oil lines

- Deluge systems

- Glycol Heater mediums

- Hypochlorite Dosing systems

- Cooling and fire water systems

- Deck repair

- Well heads

- Plugging & Abandoning a well

- Helideck net supports

- Splash zone reinforcement

- Subsea repairs

Validated in testing, proven in the field

Extensive programs have been completed on composite repair systems, putting them through rigorous tests to simulate the offshore environment and its demanding requirements. CSNRI has worked to lead those efforts on many fronts, whether it is by participating in JIPs (Joint Industry Projects) or conducting testing for specific needs and clients. Below are some of the various testing programs and studies CSNRI has participated in over the years. Click on the projects below for more information on them or contact us to discuss in more detail.

In addition to extensive testing, CSNRI has been successfully designing composite repairs for the offshore industry for decades and provides support through a rigorous training program designed to ensure the successful installation of the repair system. Combining our composite knowledge with decades of experience allows for a robust support system through training, field support, and consultation services. We have trained rope access technicians, divers, and leak sealing experts over the years, and for even more confidence in your repair, we have technicians and trainers fully qualified for offshore work who can be onsite to answer questions or assist with your repair needs. Visit our Training & Field Support page to learn more about getting trained and certified on CSNRI repair systems.

Offshore composite repair system learning opportunities

In addition to offering repair design and consultation, CSNRI also provides numerous opportunities and methods for increasing your knowledge about composite repair materials. Whether in-person meetings, industry publications, or online learning events, we are here to make sure your questions are answered. If you would like to learn more, please visit our TEC talks On-Demand page to see our library of webinars, or contact us to set up your technical meeting or learning event.

Offshore Composite Repair Solutions

Deck & Structural Repair with Composites

Addressing Axial and Bending Loads with Composites

Composites and Leak Repair Needs

Damage to process piping at a facility in Chile was attributed to Microbiologically Influenced Corrosion (MIC). CSNRI engineers developed a solution that included thousands of one- to two-foot (0.3m to 0.6m) repair lengths of AcidShield for application to the many points of corrosive damage throughout the process lines.

A natural gas pipeline operator observed external corrosion on a 24” carbon-steel pipe. To maintain reliable service, a quick, proven repair was required. CSNRI was called on to design a permanent repair. A+ Wrap was selected based on ease of installation and compatibility with condensating and underwater pipe.

At a large refinery in the UK, a 16” carbon steel crude transfer line had suffered external corrosion, including a through-wall defect. At the request of the refinery owner, CSNRI engineers surveyed the damage and recommended a six-layer application of ThermoWrap® MT to repair the defect, mitigate the corrosion, and restore the full function and structural integrity of the line.

In the northern UK, an independent British energy producer experienced failed flange welds on an 18” fire main, resulting in a leak. A solution was required that would arrest the live leak, prevent further leaks, and reinstate the strength and structural integrity of both defected flange sets. CSNRI engineers recommended a 10-layer application of ThermoWrap® MT to restore the line to its original design capacity and extend its service life.

Severe corrosion was identified in six vent stacks at the U bolt support and below the flame arrestor flanged connection. CSNRI was asked to provide an option for a permanent repair that could be completed without hot work or interruption of operation. ThermoWrap® MT was recommended to repair structural integrity of the vent stacks and extend service life, ensuring the plant would be operational past the intended decommissioning date.

Two carbon steel pipes were damaged with explosives interrupting crude transportation, the sale of which contributes much-needed revenue in the region. CSNRI was asked to assist with repairs on a small, unmanned platform off the West African coast. A solution incorporating ThermoWrap® MT was determined to be the best option for the repair.

MIDDLE EASTPipe Details 610-mm (14-inch) heavy wall structural cross member 8 m (26.25 ft) repair length 80% metal loss SummaryExtensive corrosion of several 610-mm (14-inch) heavy-wall structural cross members used to support risersCorrosion in some areas had reached 80% metal lossCSNRI trained and certified technicians carried out repairs, installing Extended SnapWrap to restore structural integrityProves…

WEST AFRICAPipe Details152.4-mm (6-inch) outlets on the main high-pressure (HP) oil/gas separator had multiple severe internal erosion defects.10.97-mm (0.43-inch) original wall thickness.Summary UT inspection revealed severe internal defects on several 152.4-mm (6-inch) outlets on the main high-pressure (HP) oil/gas separator on an offshore platform 2 local CSNRI trained technicians completed the Contour installation in 1…

UNITED KINGDOMPipe Details152-mm (6-inch) Butane Jetty Line200-mm (8-inch) Propane Jetty LineSummary External corrosion on 152-mm (6-inch) and 200-mm (8-inch) import jetty lines Pit depths in the lines were up to 5.5 mm (0.22 inch) amounting to 70% wall loss Trained local contractors carried out repairs, installing Snap Wrap to restore straight line sections. Snap Wrap…

MEXICOPipe Details Offshore Operator Pipe Diameter: 12.75” Operating Pressure: 150 psig Design Pressure: 225 psig Pipe Contents: Firewater Line Pipe Defect: Severe Cracking Summary One of our partners reached out to us about their client’s 12” firewater line that was beginning to crack due to stress and corrosion. Keeping this line operational was vital to…

ANGOLAPipe DetailsLeak one was under flange bolting on a 355-mm (14-inch) lineLeak two was damage at a GRE joint where cracks had developed between a 508-mm (20-inch) and 51-mm (2-inch) lineDesign pressure 13.2 bar (191.5 psi)Operating Pressure 8 bar (116 psi)Design Temperature 40°C (104°F) SummaryA 355-mm (14-inch) GRE cooling water line on an FPSO developed a…

CARIBBEANPipe Details 20”, 24”, 30”, 36” and 42” pipe 200 psig operating pressure 200 psig design pressure Crude oil pipeline External Corrosion SummaryThese pipeline was part of an offshore tanker filling station. The piping was suffering from external corrosion at the water/air interface. Pipeline risers were at risk of structural failure and could have developed…

West AfricaPipe Details A 4-inch (101.6-mm) Prover Loop line on a metering skid had several pinhole leaks Crude oil SummaryPinhole leaks in a 4-inch (101.6-mm) Prover Loop line on a production platform needed repairCSNRI Wet Wrap was applied to the leak and surrounding area2 local CSNRI trained technicians completed the installation in 4 daysThis repair…

West AfricaPipe Details 10-inch (254-mm) pinhole leak at a weldolet on an oil line Essential line that could result in shutdown of the platform SummaryA pinhole leak at a weldolet on a 10-inch (254-mm) oil line needed repairContour (now ThermoWrap) was applied to the leak and surrounding area2 local Clock Spring trained technicians completed the…

West AfricaPipe Details 102-mm (4-in) diameter pipe experienced internal erosion that resulted in a through-wall defect 8.56 mm (0.34 in) original wall thickness. Summary102-mm (4-in) diameter pipe experienced internal erosion that resulted in a through-wall defectTwo CSNRI trained technicians completed the 8-layer composite repair in 2 daysNo hot work was required during the repair applicationOperations…

West AfricaPipe Details Multiple through-wall defects in a 203-mm (8-in) diameter main firewater line 8.17 mm (0.32 in) original wall thickness SummaryMultiple through-wall defects in a 203-mm (8-in) diameter main firewater lineTwo CSNRI trained technicians completed the repair in 2 daysNo hot work was required during the Contour installationWorkers on an offshore platform discovered multiple…

West AfricaPipe Details 406-mm (16-inch) diameter 12.7 mm (0.5 inch) original wall thickness Multiple internal erosion defects Oil inlet to separator Summary Severe internal defects in a 406-mm (16-inch) line threatened to compromise offshore production operations. CSNRI designed a repair suitable for the line transporting hydrocarbons. CSNRI trained installers repaired the damage so production would…

PeruPipe Details A 355.6-mm (14-inch) carbon steel pipeline transporting refined product under water had sustained dents from 127 mm (5 inches) long and up to 228.6 mm (9 inches) wide (circumferential) 7 dents ranging from 3.10% to 9.90% deep required repair Installation carried out by trained divers Summary A 355.6-mm (14-inch) carbon steel pipeline transporting…

MalaysiaPipe Details 305-mm (12-inch) diameter riser with back-to-back bends 40 bar (580 psi) operating pressure 35° C (95° F) operating temperature Summary Extensive external corrosion of a riser on an offshore energy asset Corrosion extent 60% Trained local installers carried out repairs, installing SnapWrap, followed by Contour to restore structural integrity to the riser Production…

MexicoPipe Details1,067-mm (42-inch) offshore gas pipeline500 m (1,641 feet) repair lengthNew constructionNew FBE-coated (Fusion Bonded Epoxy) pipeSummaryA 1,067-mm (42-inch) gas pipeline was being pulled through a 56-inch casing and along the seabed during an offshore installationCasing Spacers and Contour WA™ (now A+ Wrap) abrasion-resistant wrap were applied to preserve line integrityMaterials shipped to the worksite…

AfricaPipe Details 26-inch (660-mm) topside production piping system Severe external corrosion Summary Clock Spring and Contour repairs were carried out to restore extensively corroded 26-inch (660-mm) topside production piping system on an offshore asset The complete pipework was subject to severe external corrosion that affected straight pipe lengths, girth welds, pipe support, tees, tight radius…

United StatesPipe DetailsA 12-inch (305-mm) carbon steel pipe transporting harsh chemicals suffered a pinhole leak caused by internal corrosion43° C (109.4° F) Operating Temperature148 C (298.4° F) Design Temperature-5° C (23° F) Ambient Temperature During InstallationSummaryInternal corrosion caused a pinhole leak on a 12-inch (305-mm) carbon steel pipe transporting harsh chemicals4 layers of axial strips…

United StatesPipe Details6-inch (152-mm) pipeline had sustained dents less than 7%12 feet (3.6 m) of water14 feet (4 m) below the mudSummary A pipeline crossing Cedar Bayou, a major recreational area in Baytown, TX, had suffered damage and needed immediate repair The underwater repair posed challenges because time and cost restraints precluded building a cofferdam…