FRP Fiber Anchors

Fiber anchors are high-strength fibers (typically carbon) combined with our Tyfo S Epoxy which forms an advanced composite, compatible with all Tyfo FRP systems.

The use of composite anchor systems to improve the performance of bonded FRP laminates was first proposed and tested in the 1990s. Unlike conventional adhesive anchors, it is not easy to proof test composite anchors in the field as they are not rigid until fully cured. By combining existing test procedures and innovative thinking, a method was developed to validate our large-diameter anchor systems according to ACI 355.4 Qualification of Post-Installed Adhesive Anchors in Concrete. Additional design properties have been obtained using ASTM D7205 Standard Test Method for Tensile Properties of Fiber Reinforced Polymer Matrix Composite Bars.

We have tested and validated the minimum bond shear strength of our anchors in both cracked and uncracked concrete and have published the minimum tensile and shear strength values for our anchors in our approved evaluation report (IAPMO UES ER-595).

With composite anchors becoming more common in FRP applications, we encourage industry professionals to put careful consideration into their specification requirements. Fyfe FRP provides no cost, no obligation technical support to design and specify these applications with confidence.

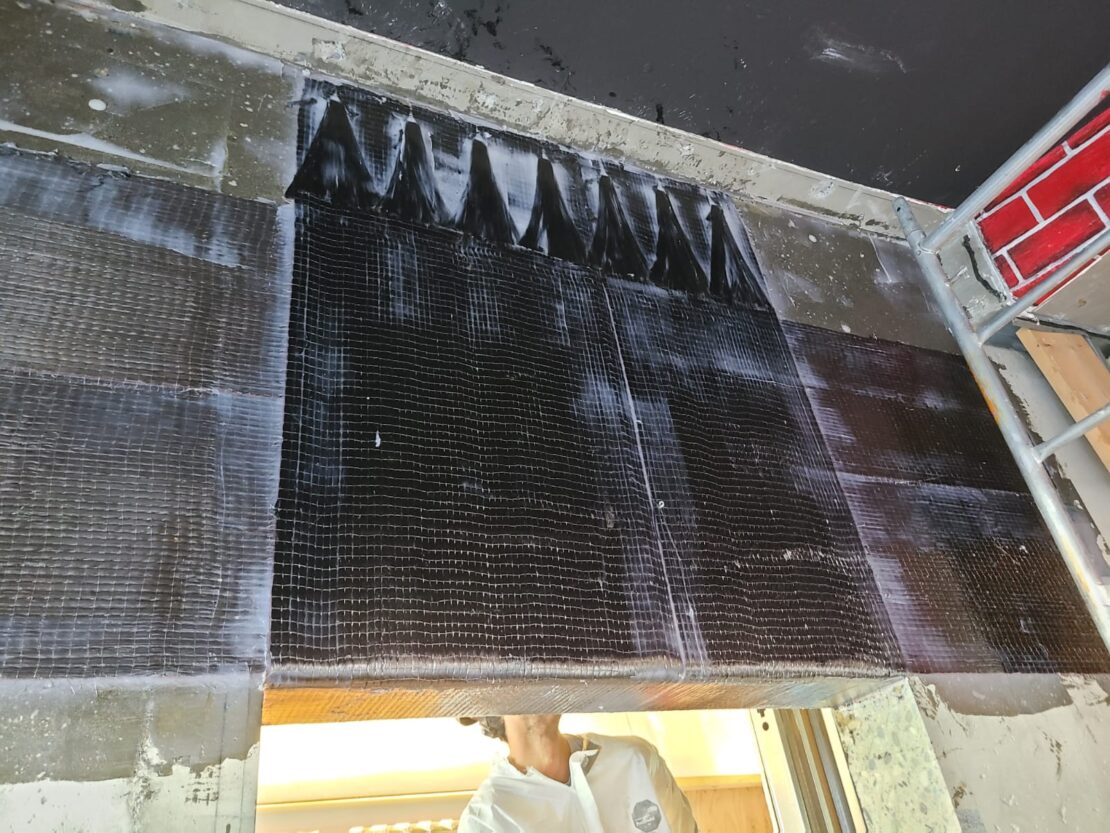

Fiber Anchor Functionality

Embedded Fiber Anchors transfer the strength from the FRP laminate into the substrate.

- Develop the strength of the FRP laminate at its termination point and at critical locations

- May be used to provide shear transfer enhancement

Splice Fiber Anchors are used to transfer the strength from one FRP laminate, through an obstacle to another FRP laminate.

- Splice anchors can be installed through wall, slab or beam obstructions.

- Splice anchors can be passed through penetrations to confine the concrete and restrict bars from buckling where there is no access to wrap all-the-way around with the FRP laminate (e.g., wall boundary elements, beam hinge locations).

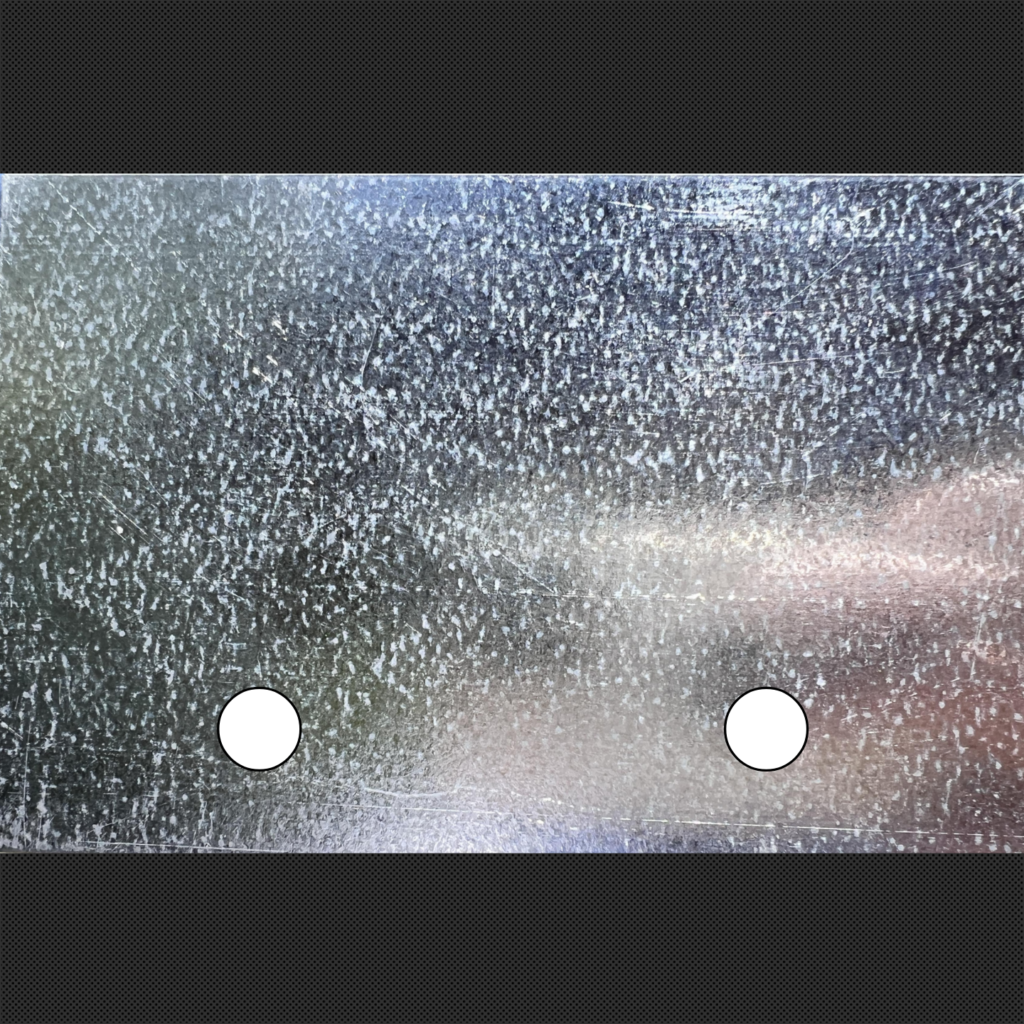

Duktil FRP Anchor Plates

Duktil FRP Anchor Plates are hybrid steel/FRP plate systems engineered to provide an alternate load delivery from externally bonded FRP into concrete. The system bonds directly to the LOCTITE Tyfo Composite systems using LOCTITE Tyfo S epoxy. It is then anchored into the concrete substrate using Hilti’s KBTZ2 wedge anchors or KH-EZ-C screw anchors. The system was developed to improve the overall performance of FRP Systems when used in retrofitting structures. The system provides an increased performance beyond traditional FRP bonding and anchorage provided by conventional FRP anchors. While strength is its primary objective, it also provides ductility given the deformation and slotting of its metallic components: The plates will deform before the anchor fails ensuring the FRP remains bonded to the concrete and providing for easy visually apparent inspection not possible with standard FRP systems. The Duktil FRP Anchor Plate system has been extensively tested to ensure its structural performance. To date, it has proven to be the most effective method to anchor externally applied FRP systems to concrete. It has the potential to fully develop up to four layers of the LOCTITE Tyfo SCH 41 System and can accommodate larger strains. Minimum design properties have been evaluated and now form part of ICC-E.S.R. 2103 report.