Summary

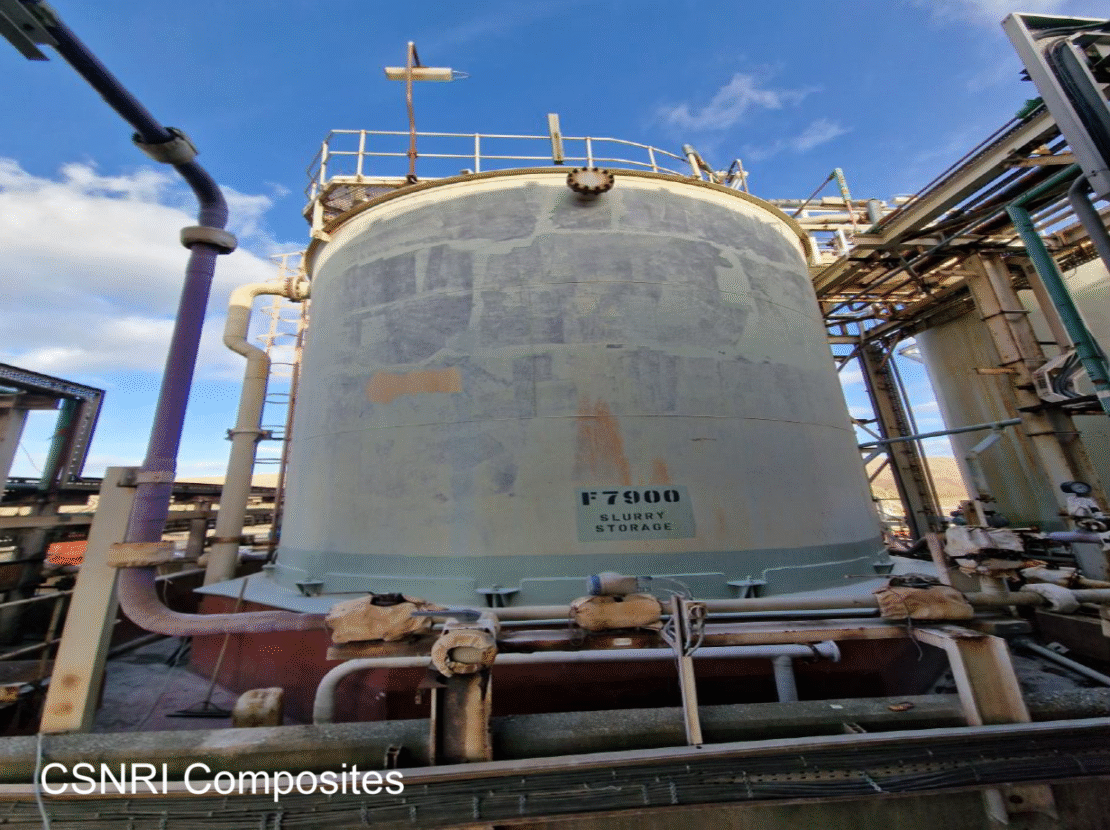

A 6.4m diameter sluice storage tank, in service for 20 years, developed severe external corrosion at its base, compromising structural integrity. Replacing the tank would have caused major production downtime and significant costs. CSNRI proposed a composite repair solution using Atlas, a high-strength carbon fiber system, to restore strength without shutdown.

Benefits

- No shutdown required – plant remained fully operational.

- Rapid execution – repair completed in just 5 days.

- Extended service life – additional 10 years of operation.

- Cost savings – over £700,000 saved compared to tank replacement.

- Minimal site disruption – CSNRI-trained technicians worked independently.

Challenge

The tank’s steel base had lost strength due to corrosion after two decades of service. Full replacement was the traditional option, but it would have caused serious production disruption and incurred high costs.Solution

CSNRI implemented a structural composite repair using Atlas, a high-strength carbon fiber system that does not require post-cure. The repair was engineered to compensate for lost steel strength and restore structural integrity.Application

An 8-layer Atlas composite system was applied externally to strengthen the corroded base of the tank. The design ensured load-bearing capability equivalent to the original steel, allowing the tank to remain in service throughout the process.Results

The repair extended the tank’s service life by 10 years while avoiding any production shutdown. The project was completed in just five days, saving the client more than £700,000 in replacement and associated costs. CSNRI-certified technicians executed the work independently, ensuring minimal disruption to site operations.