BRIDGE REHABILITATION, TYFO® SYSTEM

OVERVIEW

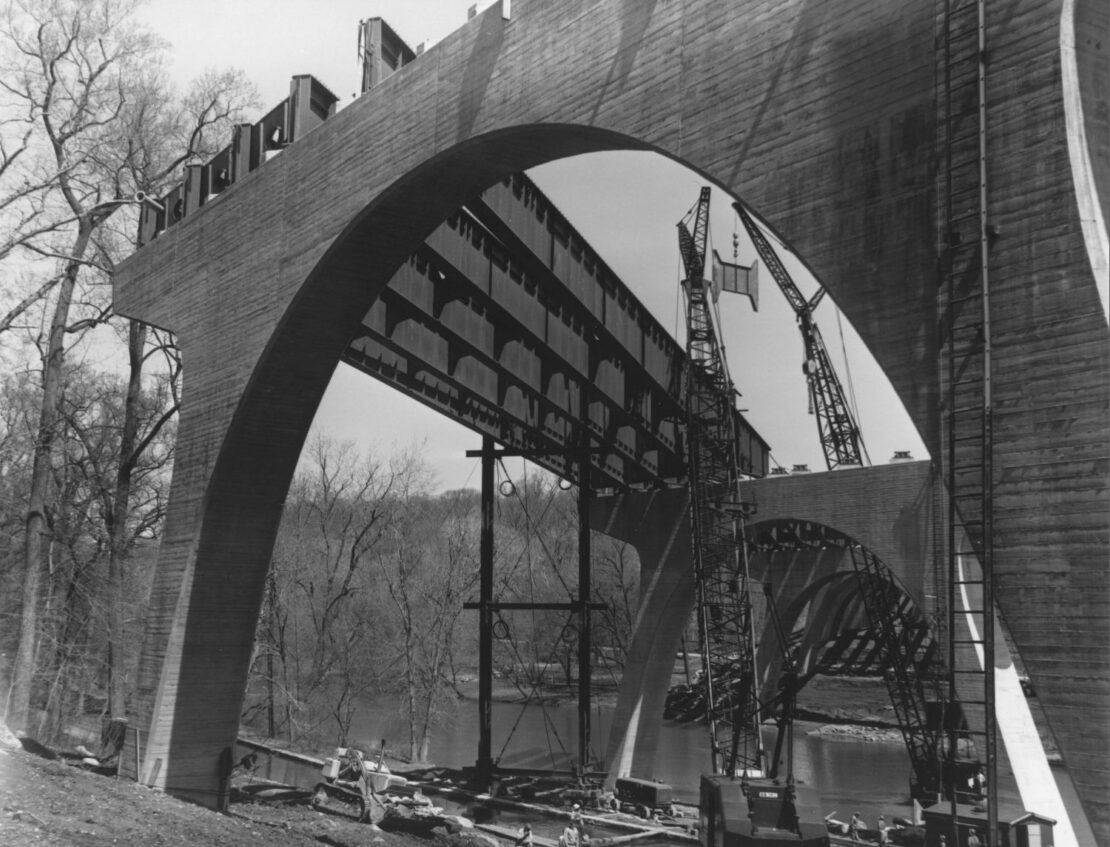

The Brandywine River bridge makes up a portion of the Delaware Turnpike, carrying I-95 traffic over the Brandywine River in Wilmington, Delaware. The bridge was constructed throughout the mid-1960s and, as it happens, the opening ceremony for the Delaware Turnpike was one of John F. Kennedy’s last public appearances before his assassination.

The bridge is currently under construction as part of a $200 million project dubbed “Restore the Corridor.”

ISSUE

When this project was in its planning phases, the structural engineers were tasked with analyzing the bridge using today’s design vehicle loads. The bridge contains two types of piers, hammerhead piers in the approach spans and arch piers in the middle spans. The structural engineers decided the strut-and-tie method was the most appropriate and accurate way to analyze these piers. This is

a relatively new analysis method that did not exist when the bridge was designed in the early 1960s. The results of the analysis indicated that the hammerhead piers required shear reinforcement throughout their cantilevered sections and negative flexural reinforcement above

their stems. The arch piers required shear reinforcement throughout their interior and exterior overhangs, positive flexural reinforcement in their interior overhangs, and negative flexural reinforcement above their verticals. Externally bonded carbon fiber reinforced polymer (CFRP) was chosen as the means of reinforcement due to its light weight, low profile, and ability to maintain the aesthetics of the substructure units once painted.

SOLUTION

In early 2021, the CFRP installation scope was awarded to Titan Industrial Services, a Fyfe certified installer based out of Baltimore, MD. CFRP installation began in the summer of 2022 and is currently on hold due to the lower winter temperatures in Wilmington, DE. On the engineering side of things, one of biggest challenges was dealing with the steep curves of the arches in areas that required shear reinforcement. Recognizing that it would be very difficult, if not impossible, to install “U” shaped wraps in these locations while keeping the vertical legs vertical, Fyfe engineers came up with an “L” shaped wrapping detail. This proved to be a successful concept as Titan Industrial Services was able to install these wraps per Fyfe’s detail without much trouble. However, construction is never without its challenges. Most of the piers were easily accessible with a manlift,

but Pier 6 required swing staging. Titan Industrial Services attached 40’-0” swing stages on each side of the capbeam of Pier 6, which made accessing the vertical faces easy. The challenge was trying to pass the saturated rolls of fiber from one swing stage to the other under the 6’-8” wide capbeam!

Another challenge was installing the positive flexural reinforcement on the undersides of the arch piers. Titan Industrial Services did not get to this until the Fall of 2022, when temperatures had started to drop. Lower temperatures result in epoxy-based systems requiring more time to cure. This can be a good thing, as it extends the working time of the epoxy, but it can also make overhead installations, where the installation team is working against the force of gravity, more difficult. To compound this, Fyfe’s design called for multiple plies of Tyfo SCH-41 2X, Fyfe’s “double thickness” unidirectional carbon fiber. This fabric is obviously heavier than Fyfe’s standard thickness Tyfo SCH-41 fabric. Closely monitoring the temperature throughout the day, only attempting to install this fiber during the warmest windows, and not trying to install too many layers at once were critical to Titan Industrial Services’ success on the project. Overall, Titan Industrial Services is pleased with what they were able to accomplish in 2022 and look forward to successfully completing the CFRP installation by the end of the 2023 season.