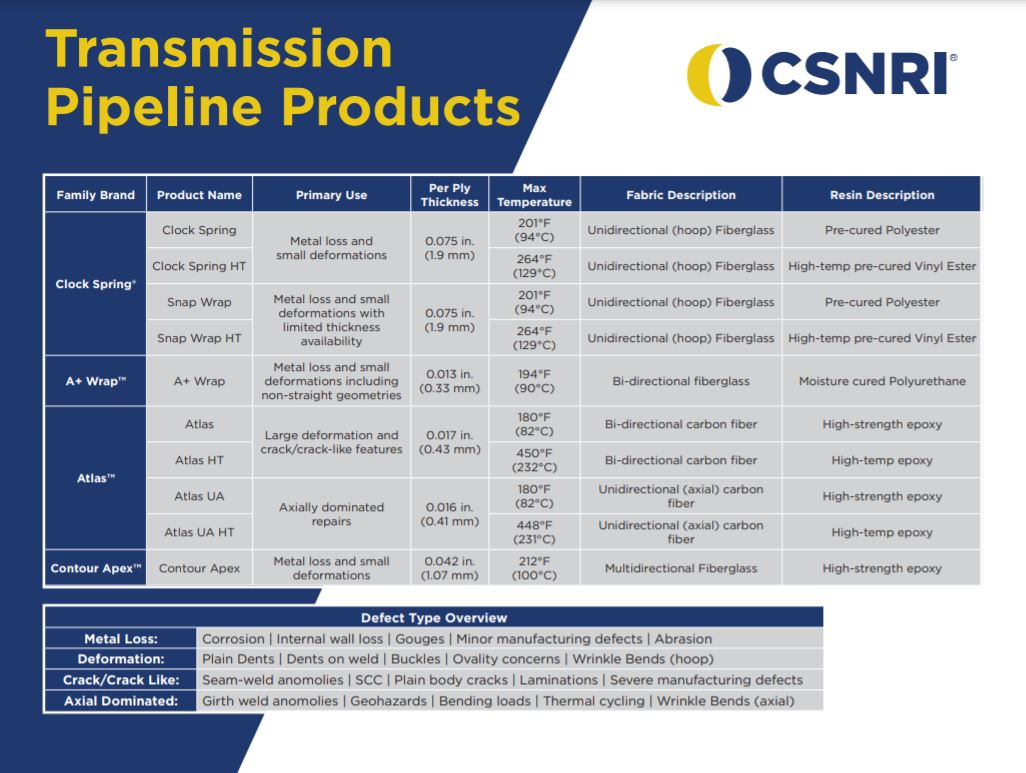

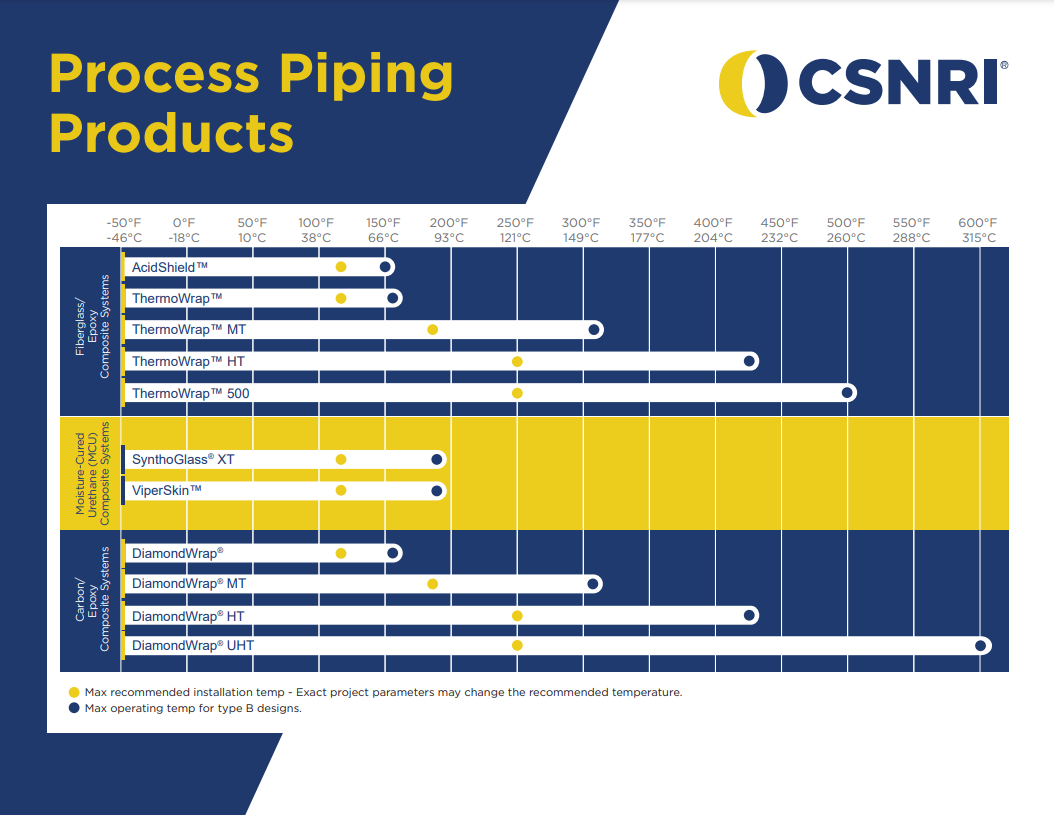

CSNRI is the world’s leading manufacturer of highly innovative, engineered products for the repair and rehabilitation of critical infrastructure. CSNRI’s composite solutions address pipeline anomalies from metal loss and small deformations to large deformations, crack/crack-like features, as well as damage to process piping working in the range of -50ºF to 597ºF (-46ºC to 314ºC).

We support our products with best-in-class design, engineering, testing, and training services to ensure proper installation and optimal performance. Our industry-leading products are easy to install, cost-effective to deploy, and durable for decades.