FLARE LINE REPAIR, TYFO® SYSTEM

OVERVIEW

In 2014, a client was looking to rehabilitate several long sections of a flare header system by encapsulating it with welded steel. The refinery’s inspection department had identified wall thinning on several sections of pipe and determined that immediate repair was needed to prevent the possibility of a hydrocarbon leak. The client had already performed several welded repairs on this header in the past and knew that since the flare header could not be shut down, its repair would be a challenge while ensuring worker safety at all times.

The client received an estimate of $1.6 million to perform the welded repair. An alternative repair method was also discussed with the client – wrapping the exterior of the pipe with carbon fiber-reinforced polymer (CFRP). CFRP is a highly engineered and rigorously tested product, developed and installed by Fyfe/Fibrwrap.

The client agreed to evaluate the alternative and Fyfe/Fibrwrap worked closely with the client to develop a solution that would both satisfy the client’s process safety requirements, and be cost effective to install. Ultimately, a high temperature Tyfo® system was proposed that met the client’s needs and specifications. The cost estimate for this solution was only $500,000.

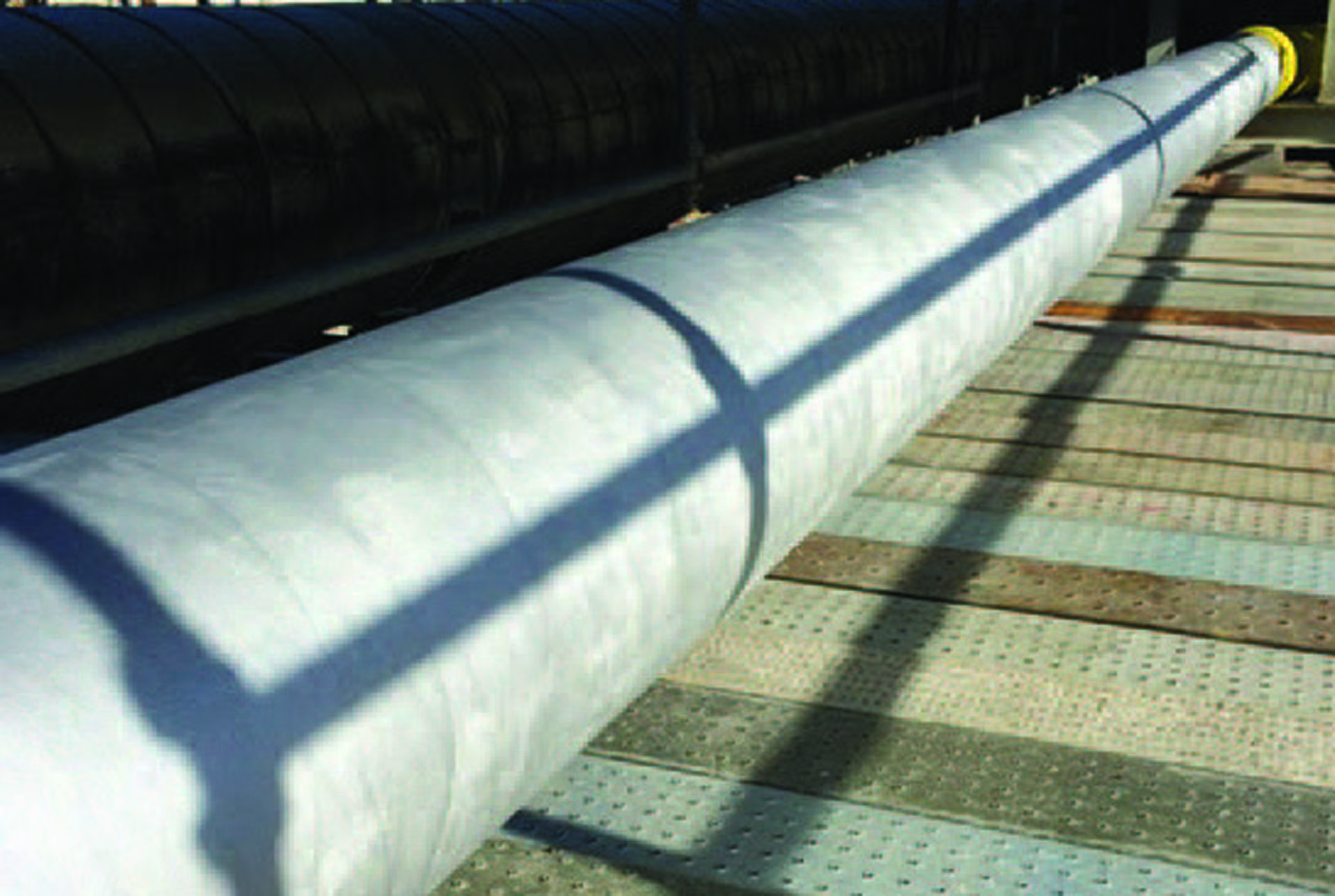

After a comprehensive technical evaluation, the client awarded a contract to Fyfe/Fibwrap in September 2014, to repair 1,000 feet of 24-inch pipe and 500 feet of 16-inch pipe. In working in partnership with Brinderson, a sister company of Aegion, the project was completed on time and on budget.

SCOPE OF SERVICES

Brinderson

- Modify structural steel pipe supports where needed, making room for the pipe wrapping process

- Prepare pipe surfaces

- Install two layers of thermal coating

- Apply carbon fiberwrap material, using the wet-layup method and high-temperature epoxy

- Apply one layer of UV-resistant coating

Fyfe/Fibwrap

- Technical analysis

- Engineered drawings

- Coating and wrapping materials

- Field support

- Quality control

PROJECT DETAILS

Project: Refinery Flare Line Repair

Location: California, United States

SAFETY ADVANTAGES

Repairing in-service piping with external carbon fiber wrap is inherently a much safer process than welding. The materials are relatively easy to handle and don’t require special PPE. Refinery hot work permits are not required and no one is put in the position of welding on a live line with thin walls.

Detailed Job Safety Analysis (JSA) sequences have been developed in collaboration with the client. Scaffolding has been provided for safe access and continuous air monitoring is performed to detect any hydrocarbon leaks. Specialized JSAs are ready in the event of a leak and for use during line lifts at the pipe supports.

Fyfe/Fibwrap uses non-VOC epoxies; respirators and additional personal safety equipment were not required.

SCHEDULE ADVANTAGES

It takes about one-third of the time to install the external wrapping system when compared to the time for a welded repair.

COST ADVANTAGES

As mentioned, the CFRP system saved the client more than $1 million.

The client also compared Fyfe/Fibrwrap’s external wrapping proposal with an alternative proposal provided by a competing installer. The alternate company purchases and installs third-party material. Their proposed cost was significantly higher.

CHALLENGES

The original design temperature of the flare piping exceeds the capabilities of any epoxy based system on the market. Therefore, Brinderson, Fyfe and Fibrwrap collaborated with the client on a solution that meets repair requirements.

The flare lines are located in a pipe rack at an elevation of approximately 30 feet. The work requires multiple lifts and extensive material handling. Fortunately, the wrapping materials are much lighter than those required for a welded encapsulation.

The section of flare line that requires the wrapping sits on 44 steel pipe supports. Wrapping of the line at the support points requires careful planning and execution due to the numerous lifts of the live, thin-walled line. Brinderson’s previous experience working on the flare line has been invaluable in planning safe execution of this work.

The client wanted to install additional thermocouples on the exterior of the piping to monitor actual temperatures during normal operation and flaring events. Fortunately, this is readily done with the CFRP wrapping system.

HIGHLIGHTS

Everyone on the team contributed to a safer, faster and more cost effective solution for this client.

There have been zero injuries of any kind and zero environmental incidents to date.