Two CSNRI technicians mobilized to carry out the repair and reinforce both repair areas using ThermoWrap MT engineered composite repair, a custom-engineered system that uses a high modulus fiberglass architecture in conjunction with a patented epoxy system. Its thick, non-crimped, glass fiber architecture and nano-tube-enriched resin combine to yield high strength characteristics. ThermoWrap MT is designed for high-temperature environments and contains a contrasting agent, this enables the repair to be monitored using common radiographic inspection methods to “see the composite repair” as well as the pipe wall.

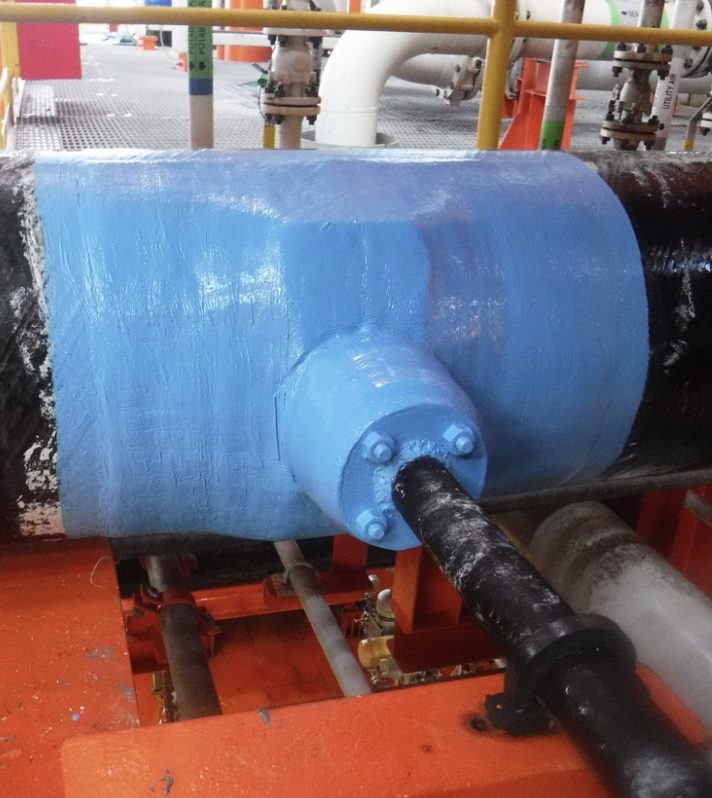

The technicians used a proprietary composite injection system to arrest the live leaks and SynthoPoxy 101 to improve the complex geometry of the lines. Once the leaks were sealed, the ECR system was installed on the first damaged line, using 8 layers of ThermoWrap MT on the 355-mm (14-inch) line and 10 layers on the 51-mm (2-inch) branch. Within 8 hours, the repairs were fully cured, and the lines made safe for continued service.

This advanced ECR allowed multiple damaged GRE lines with difficult geometry to be restored to safe operations without interrupting production and with little disruption to day-to-day operations. The final repair will enable monitoring for the duration of FPSO operations.