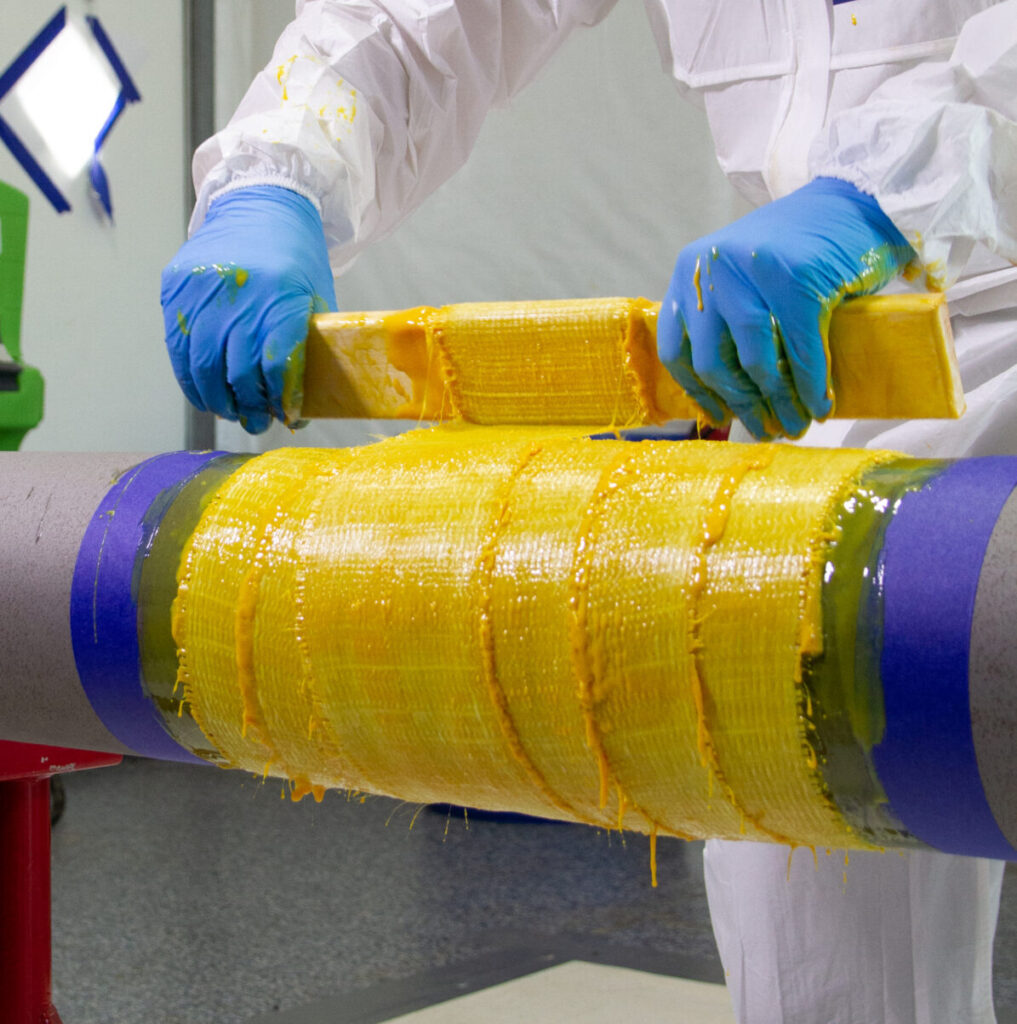

ThermoWrap is an engineered, field-saturated repair system made of proprietary fiberglass cloth applied with a two-part epoxy and a high-modulus filler material. ThermoWrap is used globally in plants, refineries, tank farms, terminals and on offshore assets as a pressure-containing repair to seal leaks and as a reinforcing repair to restore the strength of a pipe in the axial and circumferential directions. It is ideal for repairs involving complicated geometry, including tees, flanges, and varying diameter pipe.

ThermoWrap is available in multiple kit sizes for any temperature and diameter pipe and can be installed with minimal disruption to operations. It repairs through-wall defects and installs easily

in challenging environments where there is complicated pipe architecture.

ThermoWrap includes:

- ThermoWrap - operates up to 200oF (93oC)

- ThermoWrap MT - operates up to 313oF (156oC)

- ThermoWrap HT - operates up to 430oF (221oC)

- ThermoWrap 500 (pre-impregnated) - operates up to 500oF (260oC)

See product sheet for Technical Data.

Applications

- Cooling water lines

- Flare lines

- Blow down lines

- Chemical processing lines

- Energy risers

- Steel pipe

- Stack towers

- Steam piping

- Underwater pipeline

- Storage Tanks and Vessels

Benefits

- Eliminates unplanned down time for high-consequence piping

- Extends the life of aging and corroding assets

- No pipe cutting or welding

- Minimal creep ensures a long service life

- No VOCs

- Prevents future external corrosion

Compliant with

- AB-539

- ASME PCC-2

- ISO 24817

- ASME B31

- US DOT

- API

- CSA Z662